We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

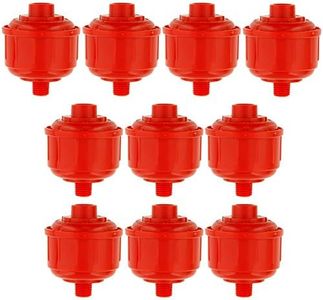

10 Best Air Compressor Line Kit 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Air Compressor Line Kit

Choosing the right air compressor line kit is essential for ensuring that your air compressor system operates efficiently and effectively. The right kit will help you maintain proper air pressure, reduce the risk of leaks, and ensure that your tools and equipment receive the air they need to function correctly. When selecting an air compressor line kit, consider the following key specifications to make an informed decision that best suits your needs.Hose MaterialThe hose material is crucial because it affects the durability, flexibility, and weight of the air compressor line. Common materials include rubber, PVC, polyurethane, and hybrid blends. Rubber hoses are durable and flexible but can be heavy. PVC hoses are lightweight and affordable but may become stiff in cold weather. Polyurethane hoses are lightweight, flexible, and resistant to kinks, making them ideal for various environments. Hybrid hoses combine the best features of rubber and PVC, offering flexibility and durability. Choose a material based on your working conditions and the level of flexibility and durability you need.

Hose LengthThe length of the hose determines how far you can move from the air compressor while using your tools. Hoses typically range from 25 to 100 feet. A longer hose provides more reach but can reduce air pressure and may be more challenging to manage. A shorter hose maintains better air pressure and is easier to handle but limits your working range. Consider the size of your workspace and the distance you need to cover when selecting the hose length.

Hose DiameterThe diameter of the hose affects the airflow and pressure delivered to your tools. Common diameters include 1/4 inch, 3/8 inch, and 1/2 inch. A larger diameter hose can deliver more air, which is essential for high-demand tools, but it can also be heavier and less flexible. A smaller diameter hose is lighter and more flexible but may not provide sufficient airflow for some tools. Match the hose diameter to the air requirements of your tools to ensure optimal performance.

Fittings and ConnectorsFittings and connectors are the components that attach the hose to the air compressor and tools. They come in various types and sizes, such as quick-connect, threaded, and barbed fittings. Quick-connect fittings are convenient and allow for easy attachment and detachment, while threaded fittings provide a secure connection. Ensure that the fittings and connectors in the kit are compatible with your air compressor and tools. Compatibility and ease of use should guide your choice.

Maximum Pressure RatingThe maximum pressure rating indicates the highest pressure the hose can safely handle, usually measured in pounds per square inch (PSI). It is essential to choose a hose with a pressure rating that exceeds the maximum output of your air compressor to prevent hose failure and ensure safety. Check your air compressor's PSI rating and select a hose with a higher maximum pressure rating to ensure reliable performance.

Temperature RangeThe temperature range specifies the range of temperatures in which the hose can operate effectively. This is important if you will be using the air compressor in extreme hot or cold conditions. Hoses that can withstand a wide temperature range are more versatile and durable. Consider the typical working environment and select a hose that can handle the temperature extremes you may encounter.

Most Popular Categories Right Now