10 Best American Made Bench Vise 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Yost HD550-C Heavy Duty 5-1/2 Inch Mechanics Work Bench Vise | Heavy Duty Woodworking & Metal Work Table with Secure Grip Swivel Base | 60,000 PSI Casting Iron Material with Extra-large Anvil Surface

Most important from

10406 reviews

The Yost HD550-C Heavy Duty Mechanic Bench Vise is a robust tool designed for professional use, particularly for mechanics and woodworking projects. Its key strengths include a strong clamping force, thanks to the 60,000 PSI ductile iron construction, and a large anvil surface that provides a stable work area.

The vise features a 5.52-inch jaw width, a maximum jaw opening of 5.30 inches, and a throat depth of 3.82 inches, which offer versatility for various tasks. The interlocking swivel base adds to its functionality, allowing for precise positioning and ease of use. Additionally, it has replaceable pipe jaws, enhancing its durability and long-term use.

However, at 50.55 pounds, it is quite heavy, which might make it less portable for some users. Also, while it's marketed as American-made, its country of origin is China, which may be a consideration for those specifically looking for products manufactured in the USA. With a high customer satisfaction rating of 4.5 out of 5 stars from over 10,000 reviews, it’s clearly a popular choice. This vise is well-suited for serious mechanics and craftsmen looking for a reliable and heavy-duty bench vise.

Most important from

10406 reviews

Forward DT08125A 5-Inch Heavy Duty Bench Vise 360-Degree Swivel Base and Head with Anvil (5", Ductile Iron)

Most important from

2195 reviews

The Forward DT08125A 5-Inch Heavy Duty Bench Vise is a robust and versatile tool designed for both industrial and DIY home use. Its jaw width and opening of 5 inches provide ample space for securing a variety of workpieces, while the 2.6-inch throat depth allows for deeper clamping. The vise is constructed from industrial-strength ductile iron, which ensures durability and longevity, capable of withstanding a significant clamp force of 5500 lbs. This material is known for its high tensile strength, further ensuring the vise can handle demanding tasks without compromising stability or performance.

Weighing in at 33 lbs, it is sturdy but still manageable for most users to install and handle. The 360-degree swivel base and rotating front head make it highly adaptable, allowing users to clamp objects at virtually any angle - a feature particularly useful for complex projects. Additionally, the vise comes with multiple sets of jaws (replaceable top jaws with microgroove tooth, built-in pipe jaws, and V-jaws), enhancing its clamping options and grip on different materials.

The large reinforced anvil is a notable benefit for tasks like grinding, cutting, and tapping. However, users should note that its weight and size might make it less ideal for smaller workspaces or benches with limited mounting options. It’s a well-rounded choice for anyone looking for a heavy-duty, multi-functional vise.

Most important from

2195 reviews

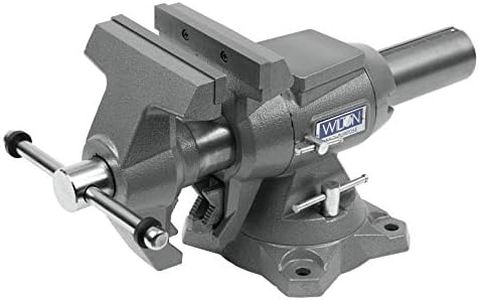

Wilton Tradesman Bench Vise, 6-1/2" Jaw Width, 6" Max Jaw Opening, 4" Throat (Model 1765)

Most important from

116 reviews

The Wilton Tradesman Bench Vise is a sturdy and reliable tool specifically designed for those who need a robust solution for various clamping tasks. With a jaw width of 6-1/2 inches and a maximum jaw opening of 6 inches, it accommodates a good range of materials and projects, making it suitable for both hobbyists and professionals alike. Its 4-inch throat depth allows for versatile clamping, which is a significant advantage in various applications.

One of the standout features of this vise is its 60,000 PSI ductile iron body, which offers exceptional strength—double that of typical gray cast iron. This ensures durability and longevity, which is important for heavy-duty use. The enclosed design keeps lubrication intact while keeping contaminants at bay, promoting smooth operation over time. Additionally, the long spindle nut enhances movement, ensuring a strong pull and reliable performance.

The large anvil on this vise is designed to withstand heavy impact, making it ideal for tasks like forming and shaping materials. Users will also appreciate the precision slide bar, which minimizes any unwanted movement of the front jaw, enhancing accuracy when clamping. However, the vise isn't without its drawbacks. At 64.3 pounds, it is quite heavy, which might complicate installation or portability for some users. Additionally, while the 6-inch maximum jaw opening is suitable for many applications, users requiring larger capacities may find it limiting.

Most important from

116 reviews

Buying Guide for the Best American Made Bench Vise

When choosing an American-made bench vise, it's important to consider several key specifications to ensure you get a product that meets your needs. A bench vise is a versatile tool used to hold objects securely in place while you work on them, making it essential for tasks such as sawing, drilling, and filing. Understanding the different specifications will help you select a vise that is durable, reliable, and suitable for your specific applications.FAQ

Most Popular Categories Right Now