We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Arbor Presses 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Arbor Presses

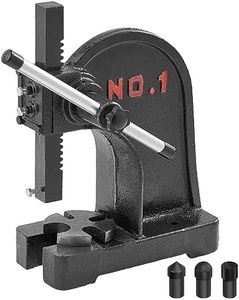

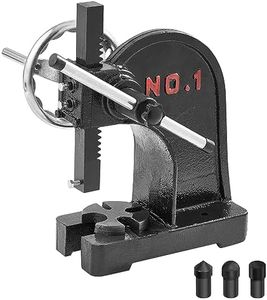

Choosing the right arbor press can make a significant difference in the efficiency and quality of your work. Arbor presses are versatile tools used for tasks such as pressing bearings, riveting, and other assembly operations. To find the best fit for your needs, it's important to understand the key specifications and how they relate to your specific requirements. Here are the main factors to consider when selecting an arbor press.Press CapacityPress capacity refers to the maximum force the arbor press can exert, usually measured in tons. This is important because it determines the types of tasks the press can handle. For light-duty tasks such as small assembly work or light pressing, a press with a capacity of 1-2 tons may be sufficient. For more demanding tasks like pressing larger bearings or heavy-duty assembly, you might need a press with a capacity of 3-5 tons or more. Consider the types of materials and the force required for your projects to choose the appropriate press capacity.

Throat DepthThroat depth is the distance from the center of the ram to the back of the press frame. This measurement is crucial because it determines the maximum size of the workpiece that can be accommodated. A larger throat depth allows for larger workpieces to be worked on. If you typically work with small to medium-sized parts, a standard throat depth will suffice. However, if you need to work on larger pieces, look for a press with a greater throat depth to ensure it can handle your projects.

Ram StrokeRam stroke is the distance the ram can travel up and down. This specification is important because it affects the range of motion and the depth to which the press can apply force. For tasks that require deep pressing or a longer range of motion, a press with a longer ram stroke is necessary. If your tasks involve shallow pressing or require less movement, a shorter ram stroke will be adequate. Assess the depth of pressing required for your typical projects to determine the appropriate ram stroke length.

Construction MaterialThe construction material of the arbor press affects its durability and stability. Most arbor presses are made from cast iron or steel. Cast iron presses are known for their durability and ability to withstand heavy use, making them suitable for industrial applications. Steel presses, while also durable, are often lighter and may be more suitable for lighter-duty tasks or portable use. Consider the frequency and intensity of use when choosing the construction material to ensure the press can withstand your working conditions.

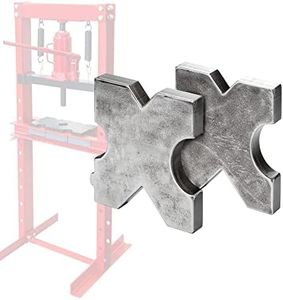

Base SizeThe base size of an arbor press determines the stability and the size of the work area. A larger base provides more stability and a larger work surface, which is beneficial for handling larger or heavier workpieces. If you work with small parts or have limited workspace, a press with a smaller base may be more appropriate. Evaluate the size of your typical workpieces and the available space in your workshop to choose the right base size.

Most Popular Categories Right Now