10 Best Barbed Wire Cutters 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Knipex 71 01 200 R SBA High Leverage CoBolt Cutters, Fencing Cutter

Most important from

346 reviews

The Knipex 71 01 200 R SBA High Leverage CoBolt Cutters are a robust choice for anyone needing to cut through tough materials like fencing and barbed wire. One of its standout features is the high-performance chrome vanadium steel construction, which ensures durability and long-lasting use. The 20-to-1 compound joint ratio provides exceptional cutting power, making it easier to cut through various materials, including components up to 5.2 mm in diameter such as bolts, nails, and rivets.

This high leverage mechanism is particularly beneficial for users needing to cut thick or hard materials with minimal effort. The non-slip grip handles enhance comfort and control, which is crucial during extended use. At 8 inches in size and weighing 12.5 ounces, the tool is relatively portable and easy to handle, though some users might find it a bit heavier compared to smaller, lighter cutters available in the market.

The angled head design may offer better accessibility in tight spaces, but its specific suitability will depend on your particular needs and working conditions. The Knipex 71 01 200 R SBA is a high-quality option for those requiring a strong, reliable tool for cutting through tough materials, though its weight and size may be a consideration for those needing a more lightweight, compact option.

Most important from

346 reviews

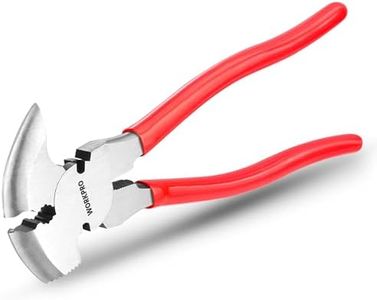

Bates- Fencing Pliers, 10.8 Inch, Multi Tool Fence Pliers, Fence Tools, Barbed Wire Fence Tools, Fencing Tools, Fence Cutter, Nail Puller Pliers, Staple Puller, Cutting Pliers

Most important from

1150 reviews

The Bates Fencing Pliers are a versatile tool designed for carpenters, handymen, and anyone dealing with fencing tasks. With a cutting capacity of 7/32 inches, these pliers can effectively manage various wire types, making them suitable for cutting barbed wire as well as performing other fencing-related tasks. The polished steel alloy construction adds durability, which is essential for long-lasting performance, while the soft plastic-coated grip ensures comfort during extended use. This feature is particularly beneficial for users who may be working on larger projects that require repetitive cutting and handling.

One of the strengths of these pliers is their multifunctionality, as they not only cut but also pull nails and staples, providing good value for the price. The corrugated hammer head and wire grips further enhance their utility, allowing for wire stretching and better manipulation of materials.

The Bates Fencing Pliers serve well in the barbed-wire cutter category, especially for those who appreciate a multifunctional tool that combines cutting and gripping capabilities. They are best suited for users who need a reliable and durable tool for fencing work.

Most important from

1150 reviews

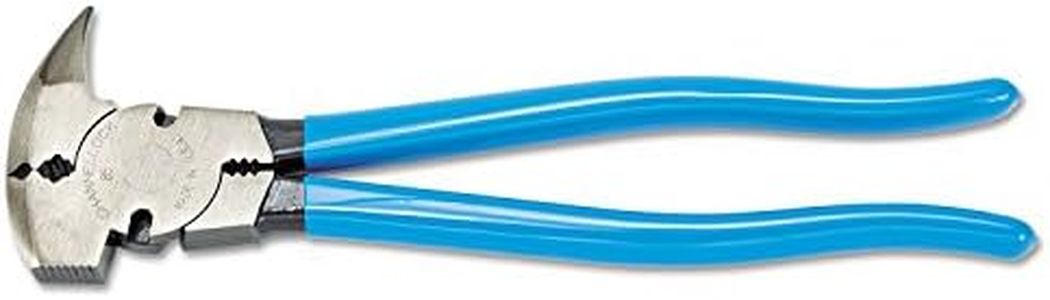

IRWIN VISE-GRIP Pliers, Fencing, 10-1/4-Inch (2078901), Blue

Most important from

2216 reviews

The IRWIN VISE-GRIP Pliers are a solid option for anyone in need of reliable barbed-wire cutters, particularly those working with fencing. Made from durable nickel chromium steel, these pliers boast impressive cutting capacity and gripping strength, making them quite effective for both metal and wood posts. The ergonomic ProTouch grips enhance comfort during use, which is especially beneficial for extended projects, minimizing hand fatigue. Their lightweight nature (1.55 pounds) adds to their portability, allowing for easy handling and transport in various work environments.

There are a few drawbacks to consider. While the cutting capacity is adequate for typical fencing tasks, those who frequently work with particularly thick or heavy-duty wire may find these pliers lacking in power compared to specialized heavy-duty alternatives. Additionally, the 10-1/4 inch length may not be suitable for all users, especially if someone prefers longer handles for greater leverage in tougher jobs.

These pliers are best suited for home improvement enthusiasts, DIYers, or professionals involved in fencing work, but anyone looking for heavy-duty solutions may want to explore other options. The IRWIN VISE-GRIP Pliers should serve you well for most everyday tasks, striking a commendable balance between comfort, durability, and performance.

Most important from

2216 reviews

Buying Guide for the Best Barbed Wire Cutters

When choosing barbed-wire cutters, it's important to consider the specific needs of your project and the type of barbed wire you will be working with. Barbed-wire cutters are specialized tools designed to cut through tough, reinforced wire, and selecting the right one can make your task easier and more efficient. Here are some key specifications to consider when picking the best barbed-wire cutters for your needs.FAQ

Most Popular Categories Right Now