10 Best Benchtop Metal Lathe 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

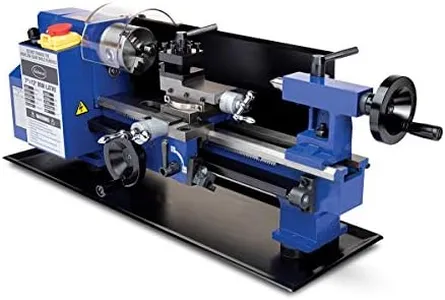

CREWORKS Mini Metal Lathe, 9" x 24" Benchtop Metal Lathe with 3 Jaw Chuck and 3000rpm Max. Spindle Speed, 1100W Metalworking Machine with LCD Display, Metal Lathe Machine

Most important from

11 reviews

The CREWORKS Mini Metal Lathe is a compact yet powerful tool suitable for small to medium-sized metalworking projects. It features an 8.7-inch swing over bed and a 23.6-inch distance between centers, which should be adequate for most hobbyist and light professional tasks. The 1100W brushless motor provides ample power and supports a variable spindle speed range from 0 to 3000 rpm, allowing for precise control over various operations such as turning, drilling, threading, and cutting. The inclusion of a digital display for monitoring speed in real-time is a notable advantage, enhancing user control and accuracy.

The lathe's 5-inch 3-jaw chuck is designed to handle both square and round objects effectively, which is beneficial for jobs requiring high precision like threading. Constructed from robust cast iron, the lathe offers durability and resistance to corrosion. Safety is also a priority, with a transparent chuck guard to protect the user while maintaining visibility. However, there are some drawbacks to consider. The lathe weighs 159 pounds, which could make it challenging to move or set up without assistance. Additionally, while it is versatile, the lathe's capabilities may be limited for more extensive, industrial-level projects.

The wide array of included components, such as brazed carbide tools, wrenches, and change gears, adds value to the purchase, providing users with all necessary tools to start their projects right away. This mini metal lathe is particularly well-suited for hobbyists, small workshops, and professionals requiring high precision in their work.

Most important from

11 reviews

Grizzly Industrial G0769-8" x 16" Variable-Speed Combination Lathe/Mill

The Grizzly Industrial G0769-8" x 16" Variable-Speed Combination Lathe/Mill is designed for versatility and compact use, making it a good fit for hobbyists or small workshops. The lathe feature offers a swing over bed of 8-1/4 inches and a swing over the cross slide of 4-5/8 inches, which is suitable for handling small to medium-sized projects. The mill component adds even more utility, with a swing of 13 inches, allowing for a range of milling operations. The motor, rated at 600W (3/4 HP), provides adequate power for most light to moderate tasks, and the variable spindle speed range (Low 50–1000 RPM, High 100–2000 RPM) gives users flexibility to tackle different materials and finishes. The dual-range spindle speeds make it adaptable for both detailed and rough work.

The size of 36" W x 20" D x 34" H ensures it fits well in smaller spaces while still offering a sturdy platform for operations. The combination lathe/mill design is a space-saver but may require frequent adjustments when switching between tasks. This can be a minor inconvenience for users needing to switch operations frequently. The tool post's flexibility is crucial for users who need to make frequent adjustments for different operations.

Jet Tools Tools - BDB-929 Belt Drive Bench Lathe 3/4HP, 115V, Single Phase with Stand (321372K) Standard

The Jet Tools BDB-929 Belt Drive Bench Lathe is a solid choice for hobbyists and small workshop users looking for a reliable metal lathe. With a swing over bed and a distance between centers that cater to most smaller projects, this lathe offers flexibility in handling various sizes of materials. The 3/4 HP motor provides sufficient power for typical tasks, while the variable spindle speed range enhances control over finishing operations. One of its key strengths is the quick change gearbox, which allows you to switch between a wide range of inch and metric threads easily, making it versatile for different projects.

Safety features are thoughtfully integrated, such as the emergency stop button and accessible safety on/off switch, which is reassuring for new users. The inclusion of backlash adjustments helps maintain precision, an important factor for quality machining. Moreover, the full-length splash guard adds an extra layer of safety, keeping debris contained during operations.

There are a few drawbacks to consider. The weight of 402 pounds may make it challenging to move or reposition without assistance. Additionally, while it’s rated highly, the relatively low power may limit its effectiveness for heavier or more demanding tasks. Users looking for a more robust, industrial-grade machine might find this model lacking in power and size. The Jet Tools BDB-929 is well-suited for hobbyists and those new to metalworking, offering a good balance of features and safety. However, those seeking a more powerful, heavy-duty machine may want to evaluate larger models in the market.

Buying Guide for the Best Benchtop Metal Lathe

Choosing the right benchtop metal lathe can be a daunting task, but with the right approach, you can find the perfect fit for your needs. A benchtop metal lathe is a versatile tool used for shaping metal by rotating the workpiece against various cutting tools. When selecting a benchtop metal lathe, it's important to consider several key specifications to ensure it meets your specific requirements. Understanding these specs will help you make an informed decision and get the most out of your investment.FAQ

Most Popular Categories Right Now