10 Best Box Cutters 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

WORKPRO Premium Utility Knife, Retractable All Metal Heavy Duty Box Cutter, Quick Change Blade Razor Knife, with 10 Extra Blades

Most important from

5510 reviews

The WORKPRO Premium Utility Knife stands out in the box-cutter category thanks to its robust construction and user-friendly design. Made from an aluminum alloy, this knife is both lightweight and highly durable, having passed a 1.5m drop test. This makes it suitable for various cutting tasks, from opening cardboard boxes to more precise work in arts and crafts. The SK5 razor blades are heat-treated for enhanced durability, providing long-lasting performance for serious cutting jobs.

One of the major strengths is the retractable blade feature, which allows for easy adjustment to three different cutting depths. This not only aids in precision but also adds a layer of safety, as the blade can be safely tucked away when not in use. Plus, replacing the blade is quick and straightforward thanks to the quick-release button, and the package includes ten extra double-use blades, adding value for users.

Ergonomically designed, the handle is comfortable to hold, making extended use less tiring. The knife's compact size makes it easy to carry, fitting comfortably in your back pocket, which is a plus for those who need a box cutter on the go.

Most important from

5510 reviews

INTERNET'S BEST Premium Utility Knife Set | Retractable Box Cutter with Rubber Handle | Heavy-Duty Cutting for Cardboard, Carpet, Plastic | Retractable Blade | Includes 2 Razor Knives & Extra Blades

Most important from

15970 reviews

The INTERNET'S BEST Premium Utility Knife Set is a practical choice for anyone needing efficient and reliable cutting tools for various tasks. With a heavy-duty design and a comfortable rubber handle, these knives are well-suited for cutting cardboard, plastic, and carpet. The retractable blade feature enhances safety, allowing users to secure the blade when not in use, which is a significant advantage for those who prioritize safe handling.

One of the standout features is the quick-change mechanism, which makes replacing blades a hassle-free experience. This is particularly beneficial for frequent users who need to switch out dull blades quickly to maintain cutting efficiency. Additionally, the set includes five extra blades, ensuring you have the necessary supplies for ongoing use without needing to purchase replacements immediately.

On the downside, while the knives are designed for heavy-duty tasks, some users may find the blade length of just 2 inches limiting for larger cutting jobs. The size may also feel a bit small for individuals who prefer a heftier tool in their hands. Although the knife's construction is robust, it’s essential to consider that continuous heavy usage may eventually wear on the metal blade. The knives are relatively lightweight at 181 grams, making them easy to handle over extended periods; however, this might also mean they lack the sturdiness that some users associate with heavier utility knives. This utility knife set is ideal for DIY enthusiasts, crafters, and anyone who frequently deals with packaging materials, making it a versatile addition to any toolbox. Whether for occasional use or more regular tasks, it strikes a balance between functionality and ease of use.

Most important from

15970 reviews

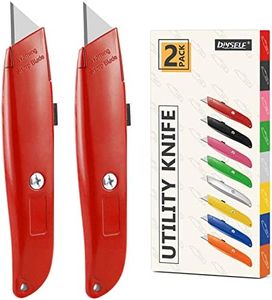

DIYSELF 2Pack Utility Knife Box Cutter Retractable Blade Heavy Duty(Red)

The DIYSELF 2Pack Utility Knife Box Cutter is a practical and economical choice for both home and industrial use. Its standout feature is the wider retractable metal blade, which is ideal for making thicker cuts on materials like cardboard, plastic, and foam board. The ergonomic handle design ensures a comfortable grip during use, reducing hand fatigue. Additionally, the safety lock tab provides an extra layer of protection by preventing the blade from slipping during operation.

The blade length of 2.36 inches is sufficient for most cutting tasks, and it is easy to replace, making it convenient for continuous use. This box cutter comes in a variety of colors, though the red version is highlighted here.

One potential downside is that the knife is designed to be economical and disposable, which may not appeal to users looking for a long-term, heavy-duty tool. Additionally, the metal blade and handle materials might feel heavier compared to plastic alternatives. Despite these minor drawbacks, the DIYSELF box cutter is a versatile and reliable tool suitable for a wide range of cutting tasks in both personal and professional settings.

Buying Guide for the Best Box Cutters

Choosing the right box cutter is essential for ensuring safety, efficiency, and ease of use. Box cutters are versatile tools used for cutting through various materials such as cardboard, plastic, and more. When selecting a box cutter, it's important to consider several key specifications to find the best fit for your needs. Here are the main factors to consider:FAQ

Most Popular Categories Right Now