10 Best Cnc Router Table 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

BOSCH RA1181 Benchtop Router Table 27 in. x 18 in. Aluminum Top with 2-1/2 in. Vacuum Hose Port

Most important from

7870 reviews

The BOSCH RA1181 Benchtop Router Table offers a work area with its 27 in. x 18 in. aluminum top, which is suitable for various woodworking projects. The aluminum material ensures durability, and the rigid mounting plate allows for precise height adjustments and compatibility with multiple routers, enhancing versatility.

The extra tall aluminum fence with adjustable faceplates and feather boards provides added precision and versatility, making it a valuable feature for detailed work. Additionally, the dedicated dust-collection port helps keep the workspace clean, which is a practical touch for maintaining a tidy and safe environment.

The accessory slot accepts various accessories, including a miter gauge, further extending the tool's usability. Storage solutions for accessories and the power cord add to its convenience and organization benefits. For those looking for a robust and versatile benchtop router table for precision woodworking, the BOSCH RA1181 is an excellent choice, emphasizing durability and practical features for clean and organized operation.

Most important from

7870 reviews

SKIL RT1323-01 Router Table and 10Amp Fixed Base Router Kit

Most important from

1161 reviews

The SKIL RT1323-01 Router Table and 10Amp Fixed Base Router Kit is a comprehensive solution for woodworking enthusiasts and small-scale professionals. One of its major strengths is the powerful 10 Amp, 2.0 HP motor, providing ample power for smooth and accurate routing. The router table itself comes with useful features such as above table adjustment, integrated bit storage, and an aluminum miter gauge slot which aid in precision and convenience during operation.

The inclusion of two featherboards, a tall adjustable aluminum fence, and MDF face plates offers great support for handling taller and larger stock with ease. This kit is designed to offer precision in routing tasks, supported by the fixed base router with soft start and speed control features which ensure a steady and controlled start every time. Users will also appreciate the live tool indicator, enhancing safety and awareness during use.

The build quality and durability are generally good, but the blend material might not be as robust as some high-end models made entirely of metal. The SKIL RT1323-01 is a solid choice for hobbyists and small workshops, offering good power, precision, and useful features at a reasonable price point.

Most important from

1161 reviews

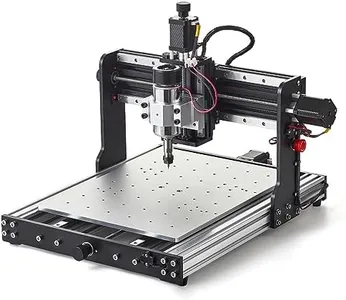

FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting

Most important from

438 reviews

The FoxAlien Masuter Pro CNC Router Machine is an upgraded all-aluminum 3-axis engraving machine designed for various materials including wood, acrylic, MDF, and nylon. One of its main strengths is the structure upgrade, featuring a linear rail on the Z-axis for improved stability and accuracy. The machine offers a large working area of 15.75” x 15.75” x 2.36”, making it suitable for most woodworking projects. Additionally, it supports extensions for larger projects, which is a great advantage for scalability.

The upgraded controller box design, with easily accessible emergency and home buttons, adds convenience and safety. Its dust-proof feature simplifies maintenance. On the compatibility front, it includes two spindle clamps (52mm and 65mm), allowing flexibility to use various spindles and modules, though some clamps need to be purchased separately. The partially pre-assembled parts and pre-wired controller box significantly reduce the assembly time to about 10-15 minutes, which is user-friendly.

However, the spindle power of 300W might be limited for heavy-duty tasks, and the maximum rotational speed of 10,000 RPM could be a constraint for some intricate projects. The robust build quality and thoughtful upgrades make it a solid choice for hobbyists and small workshop owners looking for a versatile and reliable CNC router table.

Most important from

438 reviews

Buying Guide for the Best Cnc Router Table

Choosing the right CNC router table can be a game-changer for your woodworking or metalworking projects. A CNC router table is a computer-controlled cutting machine that can be used for various materials, including wood, composites, aluminum, steel, plastics, and foams. The right CNC router table will depend on your specific needs, the type of projects you plan to undertake, and the materials you will be working with. Here are some key specifications to consider when selecting a CNC router table.FAQ

Most Popular Categories Right Now