We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

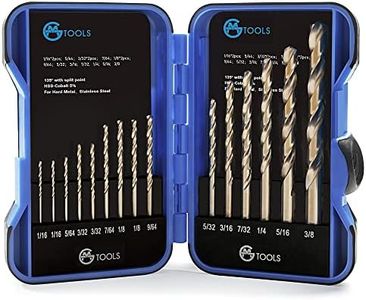

10 Best Cobalt Drill Bits For Hardened Steel 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Cobalt Drill Bits For Hardened Steel

When it comes to drilling through hardened steel, cobalt drill bits are an excellent choice due to their durability and heat resistance. These bits are specifically designed to handle tough materials, making them ideal for both professional and DIY projects. To ensure you select the best cobalt drill bit for your needs, it's important to understand the key specifications and how they impact performance. This guide will help you navigate through these specs and make an informed decision.Cobalt ContentCobalt content in drill bits is crucial because it determines the bit's hardness and heat resistance. Typically, cobalt drill bits contain between 5% and 8% cobalt. Higher cobalt content means better performance in drilling through hardened steel, as it increases the bit's ability to withstand high temperatures and maintain sharpness. For heavy-duty tasks, opt for bits with higher cobalt content (around 8%). For occasional use or less demanding tasks, bits with 5% cobalt content should suffice.

Bit SizeThe size of the drill bit is important because it determines the diameter of the hole you will drill. Drill bits come in various sizes, usually measured in inches or millimeters. Common sizes range from 1/16 inch to 1/2 inch. Choose the size based on the specific requirements of your project. For precision work or smaller holes, select smaller bit sizes. For larger holes or more general use, larger bit sizes are appropriate. Always ensure the bit size matches the needs of your task to avoid damaging the material or the bit.

Tip AngleThe tip angle of a drill bit affects its cutting efficiency and the type of material it can handle. Cobalt drill bits typically have a tip angle of 135 degrees, which is ideal for drilling through hardened steel. This angle allows for better penetration and reduces the risk of the bit wandering on the material's surface. If you are working with very hard materials, a 135-degree tip angle is recommended. For softer materials, a 118-degree tip angle might be sufficient, but for hardened steel, stick with the sharper 135-degree angle.

CoatingWhile cobalt drill bits are inherently durable, some may come with additional coatings such as titanium or black oxide. These coatings can further enhance the bit's performance by reducing friction and increasing wear resistance. Titanium-coated bits are particularly good for extending the life of the bit and improving cutting speed. If you frequently drill through hardened steel, consider bits with these coatings for added durability and efficiency. However, for occasional use, uncoated cobalt bits should still perform well.

Flute DesignThe flute design of a drill bit refers to the grooves that spiral up the bit, which help remove chips and debris from the hole. A well-designed flute can improve drilling efficiency and prevent clogging. For drilling through hardened steel, look for bits with a parabolic flute design, as this helps in better chip removal and reduces heat buildup. If you are working on deep holes or need to maintain a high drilling speed, a good flute design is essential to ensure smooth operation and prolong the bit's life.

Most Popular Categories Right Now