We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

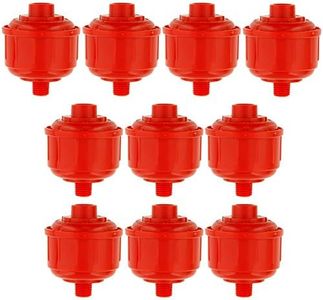

10 Best Compressed Air Dryers 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Compressed Air Dryers

Choosing the right compressed air dryer is crucial for ensuring the efficiency and longevity of your compressed air system. Compressed air dryers remove moisture from compressed air, which can otherwise cause damage to equipment and affect the quality of the end product. To make an informed decision, you need to understand the key specifications and how they align with your specific needs.Type of DryerThere are several types of compressed air dryers, including refrigerated, desiccant, membrane, and deliquescent dryers. Each type has its own advantages and is suitable for different applications. Refrigerated dryers are common and cost-effective, ideal for general-purpose use. Desiccant dryers are suitable for applications requiring extremely dry air, such as in pharmaceutical or electronics manufacturing. Membrane dryers are compact and maintenance-free, perfect for point-of-use applications. Deliquescent dryers are simple and low-cost, suitable for outdoor or remote locations. Choose the type based on the required dew point and specific application needs.

Dew PointThe dew point is the temperature at which moisture in the air begins to condense. It is a critical spec because it indicates how dry the air will be after passing through the dryer. Lower dew points mean drier air. For general industrial use, a dew point of around 35-50°F is usually sufficient. For more sensitive applications, such as in the food or pharmaceutical industries, a dew point of -40°F or lower may be required. Assess the moisture sensitivity of your application to determine the appropriate dew point.

Flow RateThe flow rate, measured in cubic feet per minute (CFM), indicates the volume of air the dryer can handle. This is important because the dryer must be able to process the amount of air your system uses. Flow rates can range from a few CFM for small applications to several thousand CFM for large industrial systems. To choose the right flow rate, calculate the total air consumption of your system and select a dryer that can handle at least that amount, preferably with some margin for future expansion.

Operating PressureOperating pressure, measured in pounds per square inch (PSI), is the pressure at which the dryer can effectively remove moisture. This is important because the dryer must match the pressure of your compressed air system. Most dryers operate within a range of 100-150 PSI, which is suitable for most industrial applications. Ensure the dryer you choose can handle the maximum pressure of your system to avoid performance issues.

Energy EfficiencyEnergy efficiency refers to how much energy the dryer consumes to remove moisture from the air. This is important for reducing operational costs and environmental impact. Energy-efficient dryers use less power and can significantly lower your energy bills. Look for dryers with energy-saving features such as variable speed drives or heat recovery options. Consider the long-term energy costs and choose a dryer that balances performance with energy efficiency.

Maintenance RequirementsMaintenance requirements refer to the frequency and complexity of servicing the dryer. This is important for ensuring reliable operation and minimizing downtime. Some dryers, like refrigerated and membrane types, require minimal maintenance, while desiccant dryers may need regular replacement of desiccant material. Consider the availability of maintenance resources and choose a dryer that fits your maintenance capabilities and schedule.

Most Popular Categories Right Now