10 Best Contour Gauges 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

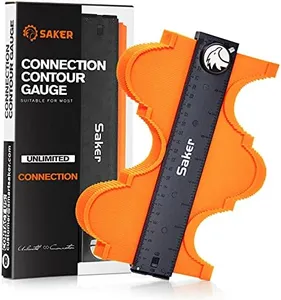

Saker Contour Gauge Profile Tool- Adjustable Lock-Precisely Copy Irregular Shape Duplicator (Unlimited Connection)

Most important from

26352 reviews

The Saker Contour Gauge Profile Tool is a handy and versatile tool designed to help users easily copy irregular shapes, making it especially beneficial for tasks like fitting tiles, carpentry, and even automotive work. This extended version allows for precise shape duplication, which is great for intricate projects involving winding pipes or circular frames. One of its standout features is the unlimited connection capability, meaning you can quickly and easily transfer shapes from various objects to your material without fuss.

The locking mechanism is another strong point; once you've captured a shape, you can secure the gauge to maintain its contours, ensuring accurate cuts every time. Made from high-quality ABS plastic, it’s both durable and lightweight, making it portable for on-the-go projects.

While the Saker contour gauge has several strengths, it may not be suitable for everyone. Users who need exceptionally deep pin depths might find it limiting, as the gauge's effectiveness can sometimes be hindered by the thickness of certain materials. Additionally, while it boasts a good build quality, some users may prefer gauges made of metal for added durability in demanding environments.

The Saker Contour Gauge is ideal for DIY enthusiasts and professionals alike who require a reliable tool for shape duplication. Its ease of use and accurate locking feature make it a strong choice, though those needing specialized functions or heavy-duty materials should consider their specific requirements before purchase.

Most important from

26352 reviews

Saker Contour Gauge (10 Inch) Profile Tool-Adjustable Lock Father's Day Gift for Men Women Dad Him Boyfriend Husband-Precisely Copy Irregular Shape Duplicator-Welding Floor Woodworking Tool Tracing

Most important from

26352 reviews

The Saker Contour Gauge is a handy tool designed for anyone who needs to replicate irregular shapes, making it particularly useful for DIY enthusiasts or professionals in woodworking and carpentry. One of the standout features is its adjustable and locking mechanism, which allows users to secure the gauge in place after tracing, ensuring precision for future cuts. The gauge is made from high-quality ABS plastic, making it durable and resistant to rust, which is a plus for longevity in various working environments.

This gauge comes in two sizes (5 inch and 10 inch), which can suit different measurement needs. It excels in applications like fitting tiles, laminate, or carpets, as well as for tasks involving pipes and circular frames. The ease of use is another benefit; users can quickly press the gauge against an object, trace the outline, and get accurate profiles for cutting.

There are a few considerations to keep in mind. The pin depth and thickness, while adequate for most applications, might not be suitable for very intricate shapes or ultra-fine detailing. Some users might find the locking mechanism could require occasional adjustments for optimal tightness. Additionally, while the ABS material is strong, it may not hold up as well as metal alternatives for heavy-duty applications.

Most important from

26352 reviews

Saker Contour Gauge Duplication-Adjustable Lock-Precisely Copy Irregular Shape-Irregular Woodworking Tracing-Must Have Tool for DIY Handyman Men Husband Dad 10 Inch+5 Inch

Most important from

8753 reviews

The Saker Contour Gauge Duplication Tool is a handy tool designed to help users accurately copy irregular shapes, making it ideal for woodworking, auto body work, and various DIY projects. One of its standout features is its adjustable and locking mechanism, which allows you to lock the pins in place after capturing a shape, ensuring precise traces every time. This makes it convenient for tasks such as fitting tiles, laminates, and carpets, and for marking precise cuts.

The tool comes in two sizes, 5 inches and 10 inches, offering versatility for different projects. It's made from high-quality ABS plastic, which is durable, rustproof, and lightweight, making it easy to carry around and use in various settings.

However, one potential drawback is that the pins might not be as thin as some users might need for capturing very fine details. Additionally, while the ABS plastic construction is durable, it might not be as sturdy as metal alternatives for heavy-duty use. Despite these minor drawbacks, the Saker Contour Gauge is a useful and practical tool for anyone involved in DIY, carpentry, or auto body work, providing an efficient way to duplicate and transfer shapes accurately.

Most important from

8753 reviews

Buying Guide for the Best Contour Gauges

Contour gauges are essential tools for anyone involved in woodworking, tiling, or any project that requires precise duplication of shapes and profiles. They help you replicate the exact shape of an object, making it easier to cut materials to fit perfectly. When choosing a contour gauge, it's important to consider several key specifications to ensure you get the best tool for your needs.FAQ

Most Popular Categories Right Now