We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Cue Lathe 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Cue Lathe

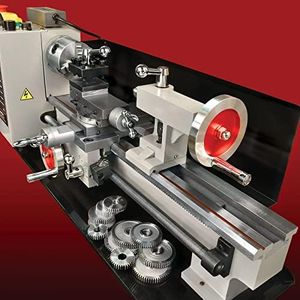

Choosing the right cue lathe is essential for anyone serious about cue making or repair. A cue lathe is a specialized machine used to shape, taper, and finish cue sticks. When selecting a cue lathe, it's important to consider several key specifications to ensure it meets your needs and provides the best results for your projects. Understanding these specifications will help you make an informed decision and choose a lathe that fits your requirements and skill level.Motor PowerMotor power determines the lathe's ability to handle different materials and the speed at which it can operate. A more powerful motor can handle harder woods and larger projects more efficiently. Motor power is usually measured in horsepower (HP). For light to moderate use, a motor with 1/4 to 1/2 HP may be sufficient. For more demanding tasks or professional use, consider a motor with 1 HP or more. Choose a motor power that matches the type of work you plan to do and the materials you will be using.

Bed LengthThe bed length of a cue lathe determines the maximum length of the cue stick that can be worked on. This is important because cue sticks come in various lengths, and you need a lathe that can accommodate the full length of the cue. Bed lengths can range from around 36 inches to over 60 inches. If you primarily work on standard-length cues, a shorter bed length may suffice. However, if you plan to work on longer cues or want more flexibility, opt for a lathe with a longer bed.

Spindle SpeedSpindle speed refers to how fast the lathe's spindle rotates, usually measured in revolutions per minute (RPM). Different materials and tasks require different speeds. Variable speed lathes allow you to adjust the RPM to suit the specific job, providing greater control and precision. For general cue making, a range of 500 to 3000 RPM is typically sufficient. If you need more versatility, look for a lathe with a wider speed range. Consider the types of materials and the level of detail in your work when choosing the spindle speed range.

TailstockThe tailstock is a movable part of the lathe that supports the end of the cue stick opposite the spindle. It is crucial for maintaining stability and accuracy during turning. A good tailstock should be easy to adjust and lock securely in place. Some tailstocks come with additional features like live centers or drill chucks, which can be useful for specific tasks. Ensure the tailstock is compatible with the types of cues you will be working on and provides the necessary support for precise work.

Tool RestThe tool rest is a horizontal bar that supports the cutting tools used to shape the cue stick. It should be adjustable and sturdy to provide a stable platform for your tools. A good tool rest allows for smooth and precise movements, which is essential for achieving a high-quality finish. Look for a lathe with a tool rest that can be easily adjusted to different positions and heights to accommodate various tasks. Consider the types of cuts and shapes you will be making when evaluating the tool rest.

Build QualityThe overall build quality of the lathe affects its durability, stability, and performance. A well-built lathe will have a solid frame, smooth operation, and minimal vibration. Materials like cast iron or steel are preferred for their strength and stability. Inspect the lathe for any signs of poor craftsmanship, such as loose parts or rough finishes. A high-quality lathe will provide better results and last longer, making it a worthwhile investment. Choose a lathe with a robust build that can withstand regular use and provide consistent performance.

Most Popular Categories Right Now