10 Best Dewalt Impact Driver 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

DEWALT 20V MAX Cordless Drill and Impact Driver, Power Tool Combo Kit with 2 Batteries and Charger (DCK240C2)

Most important from

53799 reviews

The DEWALT 20V MAX Cordless Drill and Impact Driver Combo Kit (DCK240C2) offers a solid combination of power and versatility for both professional and DIY users. The combo kit includes the DCD771 drill and the DCF885 impact driver, each designed to tackle a variety of tasks with ease. The DCD771 drill features a two-speed transmission (0-450 / 0-1500 RPM), which allows you to adjust the speed for different applications, delivering up to 300 unit watts out (UWO) of power. This makes it suitable for a wide range of drilling and fastening tasks. Additionally, its 1/2-inch single sleeve ratcheting chuck ensures a secure grip on bits, and the ergonomic handle enhances comfort and control during use. The compact and lightweight design makes it easy to maneuver in tight spaces.

The DCF885 impact driver stands out with its compact size (5.55 inches from front to back) and lightweight build (2.8 lbs), making it ideal for working in confined areas. The one-handed loading 1/4-inch hex chuck is convenient for quick bit changes, and the 3 LED light ring with a 20-second delay provides ample visibility without casting shadows, which is beneficial for low-light conditions. The 20-volt lithium-ion batteries included in the kit ensure long-lasting power, though the 1.5 amp-hour rating might require more frequent recharges during extended use.

For general use, this combo kit offers a robust and user-friendly solution with the essential features most users need.

Most important from

53799 reviews

DEWALT 20V MAX Impact Driver, 1/4 Inch, Battery and Charger Included (DCF787D1)

Most important from

656 reviews

The DEWALT 20V MAX Impact Driver (DCF787D1) is a solid choice for those looking for a reliable and efficient tool for various fastening tasks. One of its main strengths is the brushless motor, which not only increases the runtime but also enhances the durability of the tool, making it a long-lasting option. The compact and lightweight design is particularly beneficial for reaching tight spaces and working for extended periods without causing much fatigue.

Additionally, the LED light with a 20-second delay after the trigger is released is a handy feature for working in dimly lit areas, providing better visibility and precision. The inclusion of a battery and charger makes it a convenient, ready-to-use package right out of the box. The 20-volt battery offers decent power, but the 1.3-ampere battery might limit prolonged heavy-duty usage.

The 1/4-inch chuck size is typical for an impact driver, suitable for a wide range of applications but may not be ideal for larger or more specific tasks. This DEWALT impact driver is well-suited for DIY enthusiasts and professionals looking for a versatile, easy-to-use tool with the added convenience of included accessories.

Most important from

656 reviews

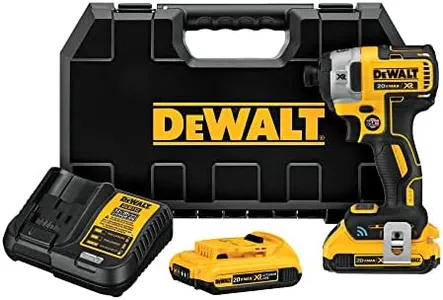

DEWALT 20V MAX XR Impact Driver, Brushless, 1/4", 3-Speed, Bare Tool Only (DCF845B)

Most important from

2220 reviews

The DEWALT 20V MAX XR Impact Driver (DCF845B) is a robust tool designed for demanding fastening applications. It features a powerful brushless motor that delivers an impressive 1825 in-lbs of torque, making it suitable for driving large diameter screws efficiently. The motor also offers a high-speed capability of up to 3400 RPM, which is advantageous for completing tasks quickly. One of its standout features is the three-speed settings, providing pro-level control and precision, which is particularly useful for varying job requirements.

Additionally, the integrated 3-LED work light enhances visibility in low-light conditions, making it a versatile tool for different environments. The impact driver is lightweight at 2.2 pounds, which helps reduce user fatigue during extended use and contributes to its ergonomic design. However, it's important to note that this model is sold as a bare tool, meaning the battery is not included and must be purchased separately. The maximum chuck size of 0.5 inches is typical for impact drivers, and the 20V battery voltage ensures strong performance.

With a high customer rating of 4.7 out of 5 stars from over 11,000 reviews, it's a well-regarded tool in its category. The tool's variable speed feature adds versatility, but potential buyers should consider the additional cost of acquiring compatible batteries if they do not already own them. This impact driver is highly effective for both professional and DIY projects, offering excellent torque, speed, and user-friendly features.

Most important from

2220 reviews

Buying Guide for the Best Dewalt Impact Driver

Choosing the right impact driver can make a significant difference in your DIY projects or professional work. An impact driver is a powerful tool designed to drive screws and bolts with high torque and minimal effort. When selecting an impact driver, it's important to consider several key specifications to ensure you get the best fit for your needs. Understanding these specs will help you make an informed decision and choose a tool that will serve you well for years to come.FAQ

Most Popular Categories Right Now