We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Diamond Sharpening 2025 in the United States

From leading brands and best sellers available on the web.How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Diamond Sharpening

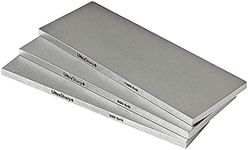

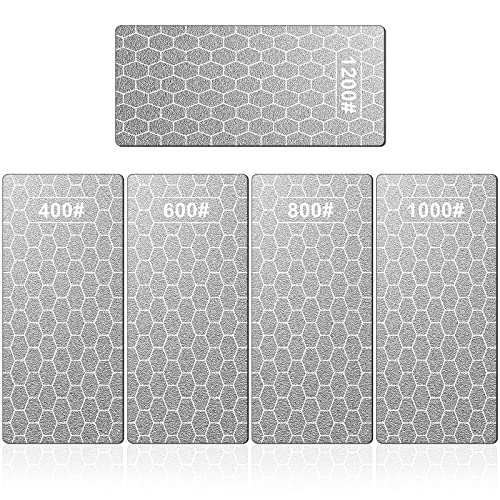

Choosing the right diamond sharpening tool can significantly impact the efficiency and quality of your sharpening tasks. Diamond sharpening tools are known for their durability and ability to sharpen a wide range of materials, including hard metals and ceramics. When selecting a diamond sharpening tool, it's important to consider several key specifications to ensure you get the best fit for your needs. Understanding these specifications will help you make an informed decision and achieve the best results in your sharpening endeavors.Grit SizeGrit size refers to the coarseness or fineness of the diamond particles on the sharpening surface. This spec is crucial because it determines how much material will be removed during sharpening and the finish of the edge. Grit sizes can range from coarse (around 200-400 grit) for heavy material removal and reshaping, to fine (around 600-1200 grit) for honing and polishing. For general sharpening tasks, a medium grit (around 400-600) is often suitable. If you need to repair damaged edges, start with a coarse grit and then move to finer grits for finishing.

Plate MaterialThe plate material is the base on which the diamond particles are bonded. Common materials include steel and aluminum. This spec is important because it affects the durability and weight of the sharpening tool. Steel plates are generally more durable and provide a stable surface, making them ideal for heavy-duty sharpening. Aluminum plates are lighter and can be easier to handle, which might be preferable for lighter tasks or portable use. Choose a plate material based on the frequency and intensity of your sharpening tasks.

Bonding MethodThe bonding method refers to how the diamond particles are attached to the plate. This spec is important because it affects the longevity and performance of the sharpening tool. Electroplated bonding involves a single layer of diamond particles bonded to the plate, which provides a sharp cutting surface but may wear out faster. Resin bonding involves multiple layers of diamond particles embedded in a resin, offering a longer lifespan and smoother sharpening experience. For occasional use, electroplated tools may suffice, but for regular or heavy use, resin-bonded tools are a better investment.

Size and ShapeThe size and shape of the diamond sharpening tool determine its usability and convenience. This spec is important because it affects how easily you can handle and store the tool. Common shapes include flat plates, which are versatile and suitable for most sharpening tasks, and rods or files, which are better for sharpening serrated edges or small tools. The size should be large enough to accommodate the items you plan to sharpen but small enough to handle comfortably. Consider the types of tools you will be sharpening and choose a size and shape that matches your needs.

Surface PatternThe surface pattern refers to the design of the diamond-coated area, such as continuous or interrupted surfaces. This spec is important because it affects the sharpening efficiency and debris removal. Continuous surfaces provide a smooth sharpening experience and are ideal for fine honing. Interrupted surfaces, with grooves or holes, help to collect metal filings and prevent clogging, making them suitable for coarser sharpening tasks. Choose a surface pattern based on the type of sharpening you will be doing and how often you need to clean the tool.

Most Popular Categories Right Now