We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

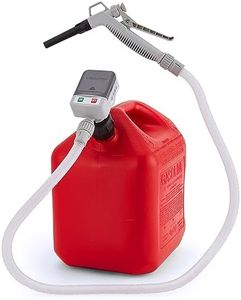

10 Best Diesel Fuel Transfer Pumps 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Diesel Fuel Transfer Pumps

Choosing the right diesel fuel transfer pump is crucial for ensuring efficient and safe fuel transfer operations. Whether you are using it for agricultural, industrial, or personal purposes, understanding the key specifications will help you select a pump that meets your needs. Here are the main factors to consider when picking a diesel fuel transfer pump.Flow RateFlow rate measures how much fuel the pump can transfer in a given time, usually expressed in gallons per minute (GPM) or liters per minute (LPM). This spec is important because it determines how quickly you can complete your fuel transfer tasks. For small-scale operations, a lower flow rate (10-20 GPM) may be sufficient. For larger operations, such as refueling heavy machinery or large tanks, a higher flow rate (20-60 GPM or more) is more appropriate. Consider the volume of fuel you need to transfer and how quickly you need to do it to choose the right flow rate for your needs.

Power SourceDiesel fuel transfer pumps can be powered by different sources, including electricity, battery, or manual hand pumps. The power source is important because it affects the pump's portability and where it can be used. Electric pumps are powerful and efficient but require access to an electrical outlet, making them suitable for stationary use. Battery-powered pumps offer more portability and are ideal for remote locations or mobile operations. Manual hand pumps are the most portable and can be used anywhere but require more physical effort. Choose a power source based on where and how you plan to use the pump.

Pump TypeThere are different types of diesel fuel transfer pumps, including rotary vane, diaphragm, and gear pumps. The pump type affects the pump's efficiency, durability, and suitability for different applications. Rotary vane pumps are efficient and suitable for high-flow applications. Diaphragm pumps are durable and can handle dirty or contaminated fuel. Gear pumps are robust and can handle high pressures. Consider the type of fuel you will be transferring and the conditions in which the pump will be used to choose the right pump type.

Material and Build QualityThe material and build quality of the pump determine its durability and resistance to wear and tear. Pumps made from high-quality materials like stainless steel or cast iron are more durable and can withstand harsh conditions. This spec is important because it affects the pump's longevity and reliability. If you will be using the pump frequently or in tough environments, choose a pump with a robust build quality. For occasional use in less demanding conditions, a pump with standard materials may suffice.

Hose Length and DiameterThe hose length and diameter affect the pump's reach and the ease of fuel transfer. A longer hose allows you to reach further distances, which is useful for large tanks or hard-to-reach areas. The diameter of the hose affects the flow rate; a larger diameter allows for faster fuel transfer. This spec is important for ensuring that the pump can meet your specific needs. Consider the distance you need to cover and the required flow rate to choose the appropriate hose length and diameter.

Safety FeaturesSafety features such as automatic shut-off, thermal protection, and explosion-proof design are crucial for preventing accidents and ensuring safe operation. These features are important because they protect both the user and the equipment. Automatic shut-off prevents overfilling, thermal protection prevents overheating, and explosion-proof design reduces the risk of fire or explosion. Choose a pump with the necessary safety features based on the potential hazards in your operating environment.

Most Popular Categories Right Now