10 Best Digital Microscope For Soldering 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

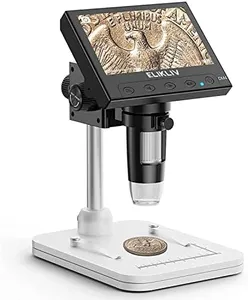

Elikliv Microscope, LCD Digital Coin Microscope 1000x, Coin Magnifier with 8 Adjustable LED Lights, PC View Compatible with Windows/MacBook, EDM4, 4.3 Inch

Most important from

7322 reviews

The Elikliv LCD Digital Microscope (Model EDM4) offers several appealing features for detailed work such as soldering. With a 4.3-inch HD display, it provides clear and crisp images, reducing eye strain and improving comfort during extended use. The magnification range from 50x to 1000x is impressive, allowing you to see intricate details, though the actual magnification may vary depending on the distance between the object and the camera. This is particularly useful for inspecting circuit boards and other small components involved in soldering. The microscope’s 8 adjustable LED lights ensure optimal illumination, which is crucial for accurate observation of fine details under varying light conditions.

The ability to connect to a PC or MacBook for a larger display is a significant advantage, making it easier to share and analyze images. However, it's important to note that the memory card needed for storing photos and videos is not included. The height-adjustable stand adds flexibility, enabling users to find the perfect angle and focus for their tasks. With a built-in rechargeable battery that supports up to 3 hours of continuous use, the microscope is quite portable, making it suitable for both indoor and outdoor projects.

One potential drawback is that the microscope might be less effective for those needing extremely high-resolution imaging for professional-level soldering, as the 720P resolution might not meet all advanced needs. Additionally, while the product is versatile and suitable for various applications, its primary design seems to cater more to hobbyists rather than professional technicians due to its build and material quality. In summary, the Elikliv EDM4 is a solid choice for amateur soldering enthusiasts and hobbyists seeking a portable and versatile digital microscope with good magnification and lighting features.

Most important from

7322 reviews

TOMLOV Autofocus 4K Digital Microscope, 8" TM4K-AF Flex Arm HDMI Micro Soldering Microscopes for Adults, Coin Microscope with Ring Light, 52MP LCD Microscopes with Screen, Electronics Repair Mat, 64G

Most important from

46 reviews

The TOMLOV Autofocus 4K Digital Microscope is a strong contender for anyone looking to enhance their soldering work, whether for professional electronics repair or hobbyist projects. With its impressive 2000x magnification and 4K video quality, users can expect sharp, detailed images, which are crucial when working on intricate soldering tasks. The auto-focus feature is particularly beneficial, as it simplifies the setup process and allows for quick adjustments without manual tweaks. This is a significant advantage, especially for beginners or those who frequently work with small components.

The microscope's 8-inch screen provides a comfortable viewing experience, and the HDMI connectivity allows it to be used with multiple displays, enhancing monitoring and productivity. The inclusion of a ring light ensures even illumination, vital for observing fine details, and the versatile flex arm stand makes it easy to position the microscope at various angles.

However, there are a few drawbacks to consider. While the auto-focus is a standout feature, some users may find it overly sensitive, leading to occasional focus jumps during use. Additionally, the microscope's weight of 5 pounds may not be ideal for those seeking a portable option. The 64GB storage is generous, but users may need to manage recording and storage more actively to ensure they don’t run out of space during long projects.

Most important from

46 reviews

Elikliv Autofocus 4K Digital Microscope EM4K-AF, 52MP Soldering Microscope for PCB Repair, Coin Inspection & Watchmaking, 2000X Magnifier Scope, 8" IPS Screen, HDMI/USB Output, 10" Stand, 64GB Card

Most important from

59 reviews

The Elikliv 4K Digital Autofocus Microscope EM4K-AF offers high-end features suitable for precise tasks like soldering, making it a valuable tool for electronics repair and detailed inspections. With an impressive 2000X magnification and stunning 4K resolution, this microscope allows for extremely detailed observation. The 52MP image quality enhances clarity, making it easier to see intricate details, which is beneficial for soldering precision. The 8-inch IPS screen further adds to this clarity, providing vibrant and sharp visuals with a wide viewing angle, ideal for professional and hobbyist use alike.

The autofocus functionality, powered by AI algorithms, reduces the need for manual adjustments, saving time and effort especially when dealing with moving objects or varying focal points. This is complemented by the responsive TOF sensor that ensures quick and accurate focal adjustments. The built-in LED lighting ensures that the working area is well-illuminated, which is crucial for soldering tasks. The microscope also boasts versatile connectivity options including HDMI and USB outputs, allowing you to project the image onto larger screens for better viewing and sharing, making it suitable for educational and collaborative environments.

The rechargeable battery adds portability, allowing for use in various settings without being tethered to a power source. The included 64GB storage card and smart controller facilitate easy capture and storage of photos and videos, enhancing the user experience. However, this advanced feature set comes at a higher price point, which might be a consideration for budget-conscious buyers. The physical size of the microscope, while offering a sturdy base and extended stand, might be less convenient for those with limited workspace. Additionally, while the high-tech features are impressive, they may present a learning curve for users not familiar with digital microscopy. Despite these considerations, the Elikliv EM4K-AF stands out as a powerful tool for detailed soldering work, coin collecting, and other precision tasks.

Most important from

59 reviews

Buying Guide for the Best Digital Microscope For Soldering

Choosing the right digital microscope for soldering can significantly enhance your precision and efficiency. A digital microscope allows you to see small details clearly, which is crucial when working with tiny components. To make an informed decision, you need to consider several key specifications that will impact your experience and results. Here are the most important specs to look at and how to choose the best fit for your needs.FAQ

Most Popular Categories Right Now