10 Best Diy 3 D Printers 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

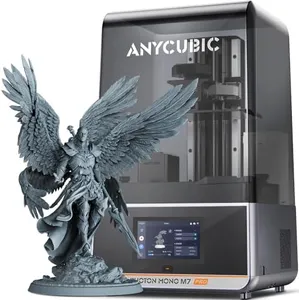

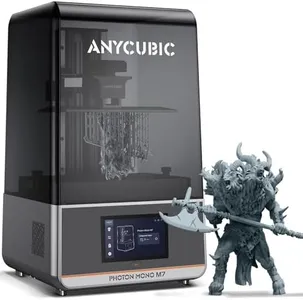

ANYCUBIC Photon Mono M7 MAX Resin 3D Printer, 13.6’’ 7K Large Resin Printer with COB LighTurbo 3.0, Flip-Open Cover Design, Intelligent-Assist Printing, Print Size 11.8'' x 11.7'' x 6.5''

Most important from

1524 reviews

The ANYCUBIC Photon Mono M7 MAX is a robust resin 3D printer tailored for DIY enthusiasts and creators looking to produce detailed models. One of its standout features is its large build volume of 11.8'' x 11.7'' x 6.5'', enabling the creation of significant projects without needing to cut or assemble pieces, which is ideal for those making props or intricate designs.

With a print resolution enhanced by the upgraded LighTurbo 3.0 technology, this printer achieves a highly precise finish, effectively minimizing layer lines. Users can appreciate the quick print speeds, reaching up to 60mm/h, which is a substantial improvement over previous models, making it more efficient for larger projects.

The printer also boasts user-friendly features such as a flip-open cover for easy access, a dynamic resin management system that maintains optimal resin temperature, and an automatic resin fill function that reduces waste. The larger resin vat allows for more extended printing sessions without the need for constant refills. The printer's weight of 62.8 pounds and its substantial dimensions may limit portability, which could be a concern for those with limited workspace. Additionally, while the build quality is solid, some users might find the learning curve a bit steep, especially if they are new to resin printing. Maintenance could also be more demanding compared to FDM printers, as resin printing typically requires more cleaning and handling precautions.

The ANYCUBIC Photon Mono M7 MAX is a strong candidate for those serious about resin printing, particularly for larger and detailed projects. However, potential buyers should consider their workspace and willingness to engage with the more hands-on nature of resin printing.

Most important from

1524 reviews

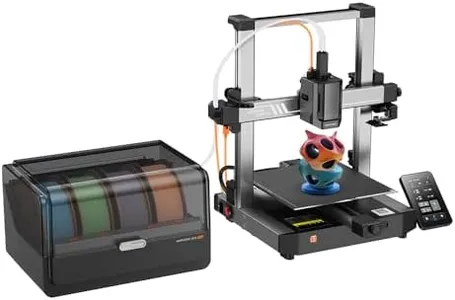

Anycubic Kobra 3 Combo Without Filament, Multicolor 3D Printer Smart Print in 4 Colors with Anycubic ACE Pro, Max 600mm/s Speed 4.3-inch Adjustable Screen, Filament Drying at All Times, 250x250x260mm

Most important from

1138 reviews

The Anycubic Kobra 3 Combo is a versatile DIY 3D printer that stands out with its ability to print up to four different colors, making it ideal for creative projects. It offers a substantial build volume of 250x250x260mm, which is sufficient for most personal and hobbyist needs. The product emphasizes smooth, high-quality prints, which suggests good print accuracy. One of its standout features is the impressive maximum print speed of 600mm/s, which allows for much faster print times compared to many competitors, making it very efficient for rapid prototyping.

It supports a wide range of filaments, including PLA, PLA+, TPU, ABS, and more, providing flexibility depending on the project requirements. The LeviQ 3.0 auto-leveling system simplifies the setup process, ensuring a hassle-free printing experience. The built-in filament drying system is a unique feature that ensures the filament remains in optimal condition, preventing clogs and print failures.

The printer does not come with any filament, which means additional purchases are necessary to get started. Additionally, while the 4.3-inch adjustable touchscreen is user-friendly, some users might find the size a bit small. The printer is also backed by a solid warranty and lifetime technical support, which adds to its appeal. This 3D printer would be well-suited for hobbyists and DIY enthusiasts looking for a fast, versatile, and reliable machine capable of multicolor prints.

Most important from

1138 reviews

Buying Guide for the Best Diy 3 D Printers

Choosing the right DIY 3D printer can be a rewarding experience, allowing you to create custom objects and parts from the comfort of your home. When selecting a 3D printer, it's important to consider several key specifications that will impact the quality, speed, and ease of use of your printer. Understanding these specs will help you make an informed decision that best fits your needs and projects.FAQ

Most Popular Categories Right Now