We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

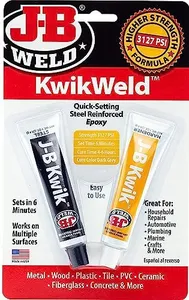

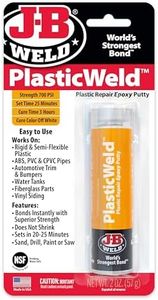

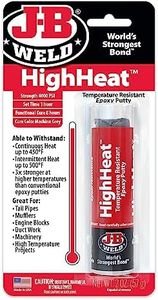

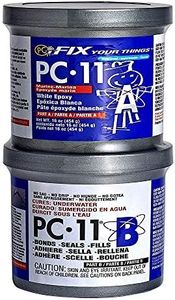

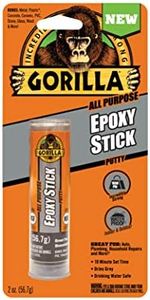

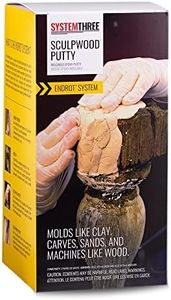

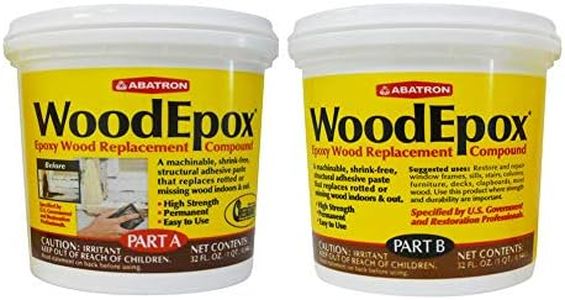

10 Best Epoxy Puttys 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Epoxy Puttys

Epoxy putty is a versatile material used for a variety of repair and construction tasks. It is a two-part compound that, when mixed, forms a strong, durable bond that can be molded and shaped before it hardens. Choosing the right epoxy putty involves understanding your specific needs and the key specifications that differentiate one product from another. Here are the key specs to consider when selecting an epoxy putty.Cure TimeCure time refers to the amount of time it takes for the epoxy putty to fully harden and reach its maximum strength. This is important because it affects how quickly you can use or handle the repaired item. Cure times can range from a few minutes to several hours. If you need a quick fix, look for a fast-curing putty. For more complex projects where you need more working time to shape and adjust the putty, a slower curing time might be more suitable.

Working TimeWorking time is the period during which the epoxy putty remains pliable and can be molded or shaped. This is crucial for applications that require precision and detail. Working times can vary from a few minutes to over an hour. If your project requires detailed work or adjustments, choose a putty with a longer working time. For quick, straightforward repairs, a shorter working time may be sufficient.

StrengthStrength refers to the durability and load-bearing capacity of the cured epoxy putty. This is important for ensuring that the repair will hold up under stress. Strength can be measured in terms of tensile strength, compressive strength, and shear strength. For heavy-duty repairs or structural applications, look for a high-strength putty. For minor repairs or cosmetic fixes, a standard strength putty will usually suffice.

Temperature ResistanceTemperature resistance indicates the range of temperatures that the cured epoxy putty can withstand without degrading. This is important for repairs that will be exposed to extreme heat or cold. Temperature resistance can vary widely, with some putties designed to withstand temperatures up to 500°F (260°C) or more. Choose a putty with a temperature resistance that matches the conditions it will be exposed to.

Water ResistanceWater resistance refers to the ability of the epoxy putty to withstand exposure to water without breaking down. This is crucial for repairs in wet or submerged environments. Some epoxy putties are specifically formulated to be waterproof and can be used for plumbing repairs or underwater applications. If your project involves exposure to moisture, ensure you select a water-resistant putty.

AdhesionAdhesion is the ability of the epoxy putty to bond to different surfaces. This is important for ensuring a strong, lasting repair. Different putties are formulated to adhere to various materials such as metal, wood, plastic, and ceramics. Consider the materials you will be working with and choose a putty that is compatible with those surfaces for the best results.

ColorColor can be an important factor if the appearance of the repair is a concern. Epoxy putties come in various colors, and some can be painted over once cured. If the repair needs to blend in with the surrounding material, choose a putty that matches the color or can be easily painted. For hidden or purely functional repairs, color may be less important.

Most Popular Categories Right Now