10 Best Gas Tank Sealer 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

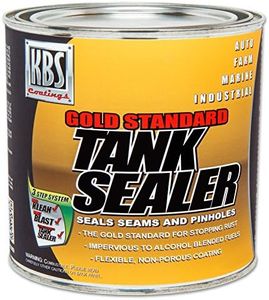

KBS Coatings 52000 Cycle Tank Sealer Kit, Complete Kit - Seals Up To 5 Gallon Tank, Lightly Pigmented Silver

Most important from

1393 reviews

The KBS Coatings 52000 Cycle Tank Sealer Kit is a comprehensive solution designed for sealing fuel tanks up to 5 gallons. It's well-suited for those needing a durable sealant for small to medium-sized tanks, particularly in automotive contexts. One of its primary strengths is compatibility; the kit includes everything needed—KBS Klean, Rust Blast, and Tank Sealer—making it a convenient option for complete tank preparation and sealing. Its chemical resistance is impressive, as once cured, it can withstand all modern fuels, alcohol additives, and most solvents, offering strong protection against chemical damage.

The lightly pigmented silver color can be appealing for cosmetic reasons, although this is secondary to its functional use. A notable feature is its ability to permanently seal pinholes and weld seams, which is crucial for maintaining the tank’s integrity and preventing leaks. Durability is another strong point, as the sealer is designed to provide long-lasting protection.

However, potential users should be aware of the curing time, which is a critical factor in planning its application. While the exact curing time isn't specified, products of this nature typically require adequate time to dry and cure properly, so patience is necessary for optimal results. The application method involves a series of steps that may require careful attention to detail to ensure effectiveness. Weighing in at just 8 ounces, the kit is lightweight, making it easy to handle, yet buyers should ensure this capacity meets their needs.

The KBS Coatings 52000 Cycle Tank Sealer Kit is ideal for those looking for a robust and reliable method to protect their fuel tanks effectively.

Most important from

1393 reviews

POR-15 Fuel Tank Sealer, Stops Rust, Corrosion and Leaks, Resistant to All Fuels, Alcohols and Additives, 8 Fluid Ounces

Most important from

4066 reviews

The POR-15 Fuel Tank Sealer is a notable option for anyone needing to seal metal fuel tanks. With its strong chemical resistance, it stands up against various fuels, alcohols, and additives, making it a reliable choice for those looking to prevent rust and corrosion. This product effectively fills in gaps and provides a non-porous seal, which is crucial for maintaining fuel integrity and preventing leaks. Additionally, the compact size (2.8 x 2.8 x 3 inches) makes it easy to handle and apply inside fuel tanks.

One of the standout features is its ability to stop and prevent rust, which is essential for prolonging the life of metal tanks exposed to harsh conditions. However, the curing time may vary, so users must plan for the time it takes to set properly, as this could delay reusing the tank.

While the product is quite effective, it does have some limitations worth considering. The compatibility is only with metal tanks, so users with plastic tanks would need to look elsewhere. Additionally, the application method requires careful handling and a clean surface for optimal performance; any debris could compromise the seal. Therefore, those unfamiliar with DIY applications may find it a bit challenging.

Most important from

4066 reviews

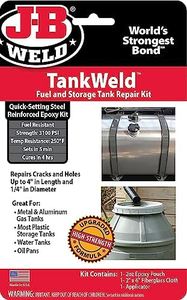

J-B Weld 2110 Metal Fuel Tank Repair Kit, Gray

Most important from

1097 reviews

The J-B Weld 2110 Metal Fuel Tank Repair Kit is designed for those needing a quick and reliable fix for their gas tanks and other metal containers. One of its standout features is its ease of use; you won’t need to remove the gas tank to make repairs. This kit allows you to mend holes up to 3/8 inches in diameter or cracks up to 4 inches long using the included epoxy putty, fiberglass cloth, sandpaper, and applicator. This makes it highly convenient for both professionals and DIY enthusiasts alike.

Its universal fit ensures compatibility with various tank types, and it's versatile enough for use on gas tanks, oil pans, and more. The chemical resistance is robust, ensuring that the repairs hold up well against gasoline and other automotive chemicals. The curing time is reasonable, allowing for efficient fixes without prolonged downtime.

Durability is another strong point; the repair is long-lasting, providing a permanent fix that stands up to daily use. However, some users might find the resin-based exterior finish less appealing compared to other finishes. This product has been on the market since 2016 and maintains a solid reputation, making it a dependable choice for quick, effective repairs.

Most important from

1097 reviews

Buying Guide for the Best Gas Tank Sealer

Choosing the right gas tank sealer is crucial for ensuring the longevity and safety of your vehicle's fuel system. A good sealer will prevent leaks, protect against rust, and maintain the integrity of your gas tank. When selecting a gas tank sealer, it's important to consider several key specifications to ensure you get the best product for your needs.FAQ

Most Popular Categories Right Now

![Galaxy S9 Plus Screen Protector Tempered Glass, [Update Version] 3D Curved Dot Matrix [Full Screen Coverage] Glass Screen Protector [Case Friendly] for Samsung S9 Plus](https://images-proxy.bestreviews.guide/dBhPbYr879zFbk2yDBetCectQkc=/0x300/https://m.media-amazon.com/images/I/51ZeCfioNhL._AC_CX679_.jpg)