10 Best Heat Transfer Papers 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

TransOurDream Tru-Iron on Heat Transfer Paper for Dark Fabric (20 Sheets, 8.5x11") T Shirt Transfers Paper for Inkjet Printer Printable Heat Transfer Vinyl for T-Shirts (TOD-7)

TransOurDream Tru-Iron on Heat Transfer Paper is a solid choice for anyone looking to transfer images onto dark fabrics like T-shirts and hoodies. One of the standout features is its compatibility with various inkjet printers, ensuring that many users can utilize it without needing specialized equipment. The paper's ability to stretch and remain intact up to twice its original size is impressive, making it suitable for custom designs that won’t easily break when worn or washed. Plus, the included reusable Teflon paper simplifies the transfer process, helping to protect the fabric during heat application.

The instructions are clear and easy to follow, which is great for beginners wanting to create DIY projects. This product is particularly well-suited for those who love crafting personalized gifts or promotional items, especially given its versatility with different fabric types.

On the downside, while the paper works well with pigment and dye inks, users must ensure they have the correct type, which could be a barrier for someone unfamiliar with printing. Additionally, the need for a heat press or iron might not appeal to everyone, as these tools can be an additional investment. Furthermore, while the transfers are stated to be machine washable, some users may find that the durability varies based on washing conditions. This heat transfer paper is a great option for hobbyists and professionals who want to create vibrant designs on dark fabrics, but it's essential to have the right equipment and ink to get the best results.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!HTVRONT Heat Transfer Paper for T Shirts - 20 Pack Mixed Light & Dark Iron on Transfer Paper,8.5" x 11" Printable Heat Transfer Vinyl for Inkjet Printer, Durable & Easy to Use

HTVRONT Heat Transfer Paper offers a versatile solution for anyone looking to create custom designs on fabric, particularly T-shirts and bags. With 20 sheets—10 for light fabrics and 10 for dark—you can easily print vibrant designs using an inkjet printer without the need for mirror printing. This feature is particularly helpful for beginners, making it easier to achieve great results right away. Its durability is impressive, as the paper can withstand up to 30 washes without fading, cracking, or peeling, making it a good choice for long-lasting creations.

On the downside, while it works well with pigment inks, it is not compatible with sublimation inks, which may limit options for some users. Additionally, while the paper performs admirably on cotton and nylon, the best transfer results are achieved on fabrics containing at least 60% cotton. This may not be suitable for other types of materials.

The ease of use extends to compatibility with cutting machines like Silhouette and Cricut, further enhancing its appeal for DIY projects. However, some users may find that the colors don't pop as much on darker fabrics as they do on lighter ones, which could be a consideration for specific design choices. HTVRONT Heat Transfer Paper is a solid choice for crafters and hobbyists looking to personalize fabric items, offering a good balance of quality and ease of use. It’s particularly ideal for those who enjoy making handmade gifts for special occasions, although attention should be paid to fabric compatibility for optimal results.

Customer Highlights

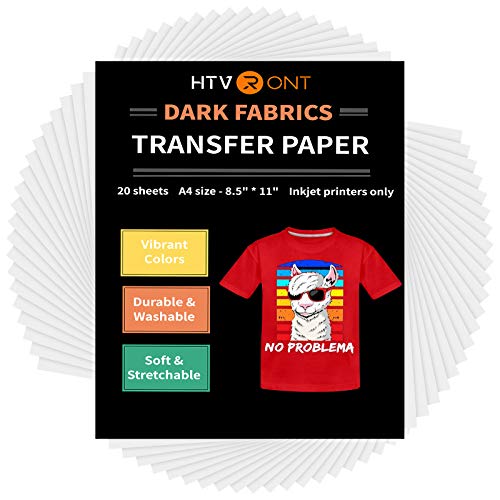

A summary of real customer reviews to highlight what shoppers are saying!HTVRONT Heat Transfer Paper for T Shirts 20 Sheets, 8.5" X 11" Printable Heat Transfer Vinyl, Vivid Color & Durable Iron on Transfer Paper for Dark Fabric

HTVRONT Heat Transfer Paper is a solid choice for anyone looking to create custom designs on dark fabrics like T-shirts. One of its main strengths is the vivid color transfer it offers, ensuring your designs pop beautifully. It's also designed for easy use; if you have an inkjet printer and a home iron, you can quickly create your projects without needing specialized equipment. This is great for craft enthusiasts who want to personalize their clothing or home decor effortlessly.

Durability is another strong point, as the paper can withstand multiple washes without fading, cracking, or peeling, making it ideal for long-lasting creations. The compatibility with inkjet printers and the specific types of inks (dye and pigment) used also makes it accessible for many hobbyists.

However, there are a few drawbacks to consider. This heat transfer paper is specifically designed for dark fabrics, so if you're looking to work on lighter materials, you'll need a different type. Additionally, while it works well for DIY projects, using it requires some practice to get the application temperature and time just right (320-338°F for 8-12 seconds). Some users might find this a bit tricky at first. It's also worth noting that this product is not standard heat transfer vinyl (HTV); it’s a printable version that can be used with cutting machines, which may confuse some beginners. Despite these minor limitations, HTVRONT Heat Transfer Paper could certainly meet your crafting needs.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Buying Guide for the Best Heat Transfer Papers

Choosing the right heat transfer paper is crucial for achieving high-quality prints on fabrics and other materials. Heat transfer papers are used to transfer images, designs, or text onto various surfaces using heat and pressure. The right paper can make a significant difference in the durability, vibrancy, and feel of the final product. Here are some key specifications to consider when selecting heat transfer papers and how to choose the best one for your needs.FAQ

Most Popular Categories Right Now