10 Best Impact Drivers 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

DEWALT 20V MAX XR Impact Driver, Brushless, 1/4", 3-Speed, Bare Tool Only (DCF845B)

Most important from

11667 reviews

The DEWALT 20V MAX XR Impact Driver stands out as a robust choice for both professionals and DIY enthusiasts looking for a reliable tool for fastening tasks. With a powerful brushless motor delivering up to 1825 in-lbs of torque and a maximum speed of 3400 RPM, this impact driver can handle larger diameter screws with ease, making it ideal for tough job site conditions. The ability to adjust speed with its three-speed settings provides pro-level control and precision, allowing users to adapt to different materials and applications effectively.

One of the key advantages is its lightweight design at just 2.2 pounds, which enhances ergonomics and reduces fatigue during extended use. The integrated 3-LED work light is another thoughtful feature, improving visibility in dimly lit spaces, enhancing usability for those working in various environments.

There are some considerations to keep in mind. This model is sold as a bare tool, meaning users will need to purchase a compatible battery and charger separately, which could be an unexpected additional expense for some buyers. Additionally, while it boasts a maximum chuck size of 0.5 inches, it may not accommodate larger bits that some heavy-duty tasks require, which could limit its versatility for certain projects. The DEWALT 20V MAX XR Impact Driver is an excellent tool for those focused on power and precision in fastening applications, but prospective buyers should consider their battery needs and project requirements before making a purchase.

Most important from

11667 reviews

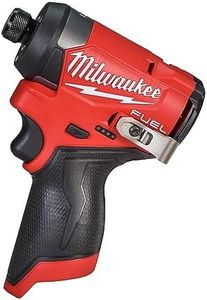

Milwaukee 2953-20 18V Lithium-Ion Brushless Cordless 1/4'' Hex Impact Driver (Bare Tool), Red

Most important from

1612 reviews

The Milwaukee 2953-20 18V Lithium-Ion Brushless Cordless Impact Driver is designed to enhance productivity on job sites with its impressive features. One of its standout aspects is the high torque of 2000 in-lbs, which makes it capable of tackling tough fasteners with ease. The maximum rotational speed of 3900 RPM ensures quick driving, allowing users to complete tasks faster without compromising on power. This speed is complemented by the 4-Mode Drive Control, which offers versatility for different applications, making it suitable for both delicate and heavy-duty jobs.

The ergonomic design, weighing only 2.2 pounds, embraces user comfort, especially during extended use, reducing fatigue. Its Tri-LED lighting provides excellent visibility in dark working conditions, a thoughtful feature. Additionally, the variable speed control allows for smooth acceleration, which helps prevent stripping screws—a common issue with impact drivers.

One significant drawback is that this is a bare tool, meaning that batteries and chargers must be purchased separately, which can increase the total cost for users who do not already own compatible Milwaukee batteries. While the impact driver has a robust construction and excellent performance, its lack of included accessories could be a barrier for novice users or those looking for a complete kit.

Most important from

1612 reviews

DEWALT 20V MAX XR 1/4 Inch Cordless Quiet Hydraulic Impact Driver, Bare Tool Only (DCF870B)

Most important from

54 reviews

The DEWALT 20V MAX XR 1/4 Inch Cordless Quiet Hydraulic Impact Driver, Bare Tool Only (DCF870B), is a powerful tool that stands out in the impact driver category. One of its main strengths is its high torque, making it ideal for driving large screws and bolts with ease. The tool also boasts impressive speed, allowing you to complete tasks quickly. Additionally, it operates quietly, reducing noise disturbances by up to 57%, which can be a significant advantage if you’re working in a noise-sensitive environment.

This model is also faster than some competitors, including Milwaukee, which may enhance productivity. However, it’s important to note that the product doesn’t come with batteries, so you’ll need to purchase them separately. In terms of ergonomics, the driver is relatively lightweight at 2.55 pounds, making it easy to handle. The compact design (4.6 x 3.4 x 8.23 inches) aids maneuverability in tight spaces. The chuck size of 1/4 inch is standard, fitting most common bits. The included belt hook is a convenient feature for portability.

Despite these benefits, the lack of included batteries and being bare tool only could be seen as drawbacks. This impact driver is best suited for users who already own DEWALT 20V batteries or are willing to invest in them separately.

Most important from

54 reviews

Buying Guide for the Best Impact Drivers

Choosing the right impact driver can make a significant difference in your DIY projects or professional work. An impact driver is a powerful tool designed to drive screws and bolts with high torque and minimal effort. To find the best fit for you, it's essential to understand the key specifications and how they align with your needs. Here are the main specs to consider when selecting an impact driver.FAQ

Most Popular Categories Right Now