10 Best Laser Cutting Machines 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

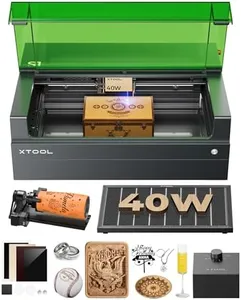

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

The xTool S1 40W Laser Cutter and Engraver is a robust machine designed for diverse and large-scale projects. One of its main strengths is the powerful 40W laser, which effortlessly cuts through thick materials like 18mm cherry wood in a single pass. The large cutting area of 23.93” x 15.16” makes it suitable for big projects such as door signs or batch engraving items like dog tags. With cutting speeds of up to 600mm/s, it ensures high productivity and efficiency.

The precision is enhanced by xTool’s patented Pin-point Positioning technology, which allows for detailed engravings, even on curved surfaces, making it versatile for various materials including wood, metal, and acrylic. Additionally, the inclusion of AutoPassthrough Technology is beneficial for handling extended projects up to 118 inches in length. The machine is user-friendly, coming ready to use straight out of the box, with an auto-focus feature and intuitive software (xTool Creative Space) that simplifies the engraving process, even for beginners.

Safety is a top priority with the xTool S1. It includes a protective cover that filters 99% of laser light, multiple flame sensors, an emergency stop button, and a lid-open stop feature, making it safe to use around children and pets. However, the machine is quite heavy at nearly 80 pounds, which might be cumbersome for some users to move. Additionally, it operates with a cooling system to manage the laser heat, which is essential for maintaining performance and longevity. The product is built to last, with rigorous testing ensuring its durability and reliability. Users should consider the weight and space requirements before purchasing.

Customer Highlights

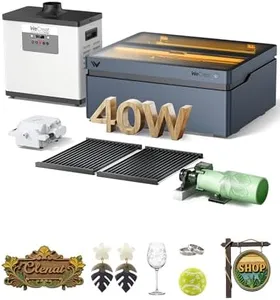

A summary of real customer reviews to highlight what shoppers are saying!WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

The WECREAT Vision 20W Laser Engraver is a well-rounded machine suited for both hobbyists and professionals. With a powerful 20W laser, it offers high precision with 0.01mm accuracy and a rapid cutting speed of 600mm/s, making it efficient for batch engraving. The cutting area is adaptable due to its auto-lifting design, accommodating materials up to 5.5 inches thick, which adds convenience by eliminating manual adjustments. The engraver can handle various materials such as wood, metal, acrylic, and tumblers, making it versatile for different DIY projects.

The intelligent air assist feature ensures cleaner cuts and reduces burning, while the unique laser beds minimize burn marks compared to traditional honeycomb beds. Safety is emphasized with the FDA Class 1 rating and a fully enclosed design that stops operation if the lid is opened, along with eye-protection measures that filter 99% of laser light. The built-in HD camera and quick view matrix enhance positioning accuracy and workflow efficiency, reducing material waste.

Software compatibility is excellent, supporting both WECREAT's proprietary software and Lightburn, along with access to a rich library of ready-to-print images and editable projects. The machine is relatively heavy at 65.4 pounds, which might be cumbersome for users looking for portability. The product dimensions are quite large, so workspace requirements need consideration. Despite these minor drawbacks, the WECREAT Vision 20W Laser Engraver offers robust features and flexibility, making it a solid choice for detailed engraving and cutting tasks.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!xTool S1 20W Laser Engraver and Cutter Machine with Air Assist & Honeycomb, 23.93" x 15.16" Bed Size, Beginner-Friendly, Laser Engravering Machine for Wood and Metal, Acrylic, etc. - Basic Bundle

The xTool S1 20W Laser Engraver and Cutter Machine stands out with its powerful 20W laser, capable of cutting through 10mm cherry wood in a single pass, making it suitable for various materials including wood, metal, acrylic, and leather. Its spacious 23.93" x 15.16" bed size allows for large projects, and the impressive cutting speed of up to 600mm/s enhances productivity.

Pin-point Positioning technology and AutoPassthrough Technology ensure high precision and accuracy, even on curved surfaces and extended projects up to 118 inches long. The machine is beginner-friendly, featuring auto-focus and intuitive xTool Creative Space software with AI-powered design capabilities, making it accessible for users with no design skills. Safety is prioritized with a protective cover, flame sensors, and emergency stop features, making it safe to use around children and pets.

The robust aerospace-grade aluminum frame ensures durability and stability, with rigorous testing providing reliability. The machine supports multiple laser modules for versatility, although accessories are sold separately unless part of a bundle. However, at 44 pounds, it is relatively heavy, and the high power might be overwhelming for casual hobbyists. This makes it a well-rounded machine suitable for serious crafters and small businesses looking for a powerful, precise, and user-friendly laser cutter and engraver.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Buying Guide for the Best Laser Cutting Machines

Choosing the right laser cutting machine can be a daunting task, but with the right approach, you can find a machine that perfectly fits your needs. Laser cutting machines are used for a variety of applications, from industrial manufacturing to hobbyist projects. To make an informed decision, you need to understand the key specifications and how they relate to your specific requirements. Here are the main specs to consider when selecting a laser cutting machine.FAQ

Most Popular Categories Right Now