10 Best Laser Engravers 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

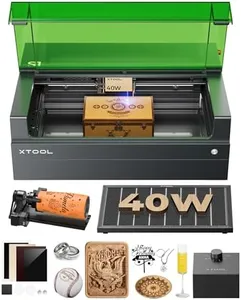

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

Most important from

136 reviews

The xTool S1 40W Laser Cutter and Engraver stands out in the laser engraving market with its robust 40W laser power, allowing it to cut through substantial materials like 18mm cherry wood in a single pass. Its expansive engraving area of 23.93" x 15.16" makes it suitable for large projects, and its 600mm/s speed ensures efficient processing. This machine is versatile in terms of material compatibility, working well with wood, metal, acrylic, and more. The precision and resolution are enhanced by xTool’s patented Pin-point Positioning and AutoPassthrough Technology, which are ideal for detailed and 3D engravings on curved surfaces.

The intuitive xTool Creative Space software further simplifies the engraving process, even for beginners, by offering AI-powered design assistance and over 1,000 project tutorials. The machine's safety features are commendable, with a Class 1 safety rating, protective cover, flame sensors, and emergency stop functions ensuring a secure operating environment.

On the downside, the product is quite heavy at 79.2 pounds, which might be cumbersome for some users. Additionally, while the enclosed design is excellent for safety, it may limit accessibility for some intricate projects. Despite these minor setbacks, the xTool S1 40W Laser Cutter and Engraver is a high-quality, durable choice for both hobbyists and professionals engaged in various engraving and cutting tasks.

Most important from

136 reviews

CREALITY FALCON2 22W Laser Engraver Machine with Air Assist and Rotary Roller, 220W High Accuracy Laser Engraver and Cutter Machine for Cylindrical Objects, 25000mm/min Faster Engraving

Most important from

80 reviews

The 22W Laser Engraver Machine from Creality Falcon offers impressive laser power, making it suitable for both engraving and cutting tasks. With a high engraving speed of up to 25,000mm/min, it efficiently supports small business ventures and hobbyists looking for quick, batch processing. Its laser power is capable of cutting through 15mm wood or 10mm black acrylic in one pass, indicating strong performance for various materials such as wood, acrylic, metal, and glass. The included air assist helps maintain clean cuts and reduces material surface temperature to prevent distortion and discoloration during engraving.

The 4 in-1 Rotary Roller adds versatility by enabling engraving on cylindrical objects of various sizes, making it ideal for personalized gifts or home decor items. Precision is a notable strength with this engraver, ensuring accurate and detailed work. The machine is compatible with popular software like LaserGRBL and LightBurn, which supports both Windows and macOS, and allows for offline use via a TF card. The cooling system provided by the integrated air assist helps maintain performance and safety.

The engraver features an anti-UV filter cover, emergency stop button, and a safety lock, which are important for operator protection. On the downside, the machine is manual in operation, which might require a learning curve for beginners. The assembly time is relatively quick, around 10-20 minutes, but it might still be a consideration for those looking for a plug-and-play solution. In summary, the Creality Falcon 22W laser engraver is a powerful and precise tool suitable for both professional and hobbyist use, offering extensive material compatibility and robust safety features.

Most important from

80 reviews

WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

Most important from

57 reviews

The WECREAT Vision 20W Laser Engraver offers a potent 20,000mW laser power, making it suitable for both engraving and cutting applications. It boasts a high precision of 0.01mm, ensuring detailed and accurate designs. With an engraving area sufficient for most projects, it can handle materials like wood, acrylic, and metal, making it versatile in material compatibility.

One standout feature is its intelligent air assist, which enhances the quality of engravings by providing cleaner surfaces and reducing burn marks. The auto-lifting enclosure is a significant convenience, eliminating the need for manual adjustments for varying material heights, which saves time and effort. The built-in smart HD camera and quick view matrix simplify the setup and alignment process, making efficient use of materials and minimizing waste.

Safety is well-addressed with its fully enclosed design and FDA Class 1 rating, providing peace of mind with eye protection and automatic shutoff if the lid is opened. The software compatibility with both proprietary and Lightburn software, along with a rich library of ready-to-use designs, caters to both beginners and professionals. However, it’s relatively heavy at 65.4 pounds, which might be cumbersome for some users. It's a reliable and advanced laser engraver with innovative features, perfect for those who prioritize precision, versatility, and safety in their engraving tasks.

Most important from

57 reviews

Buying Guide for the Best Laser Engravers

Choosing the right laser engraver can be a bit overwhelming, but with the right approach, you can find the perfect fit for your needs. Laser engravers are versatile tools used for engraving designs on various materials like wood, metal, plastic, and more. To make an informed decision, you need to consider several key specifications that will determine the performance and suitability of the engraver for your specific projects. Understanding these specs will help you match the engraver's capabilities with your requirements, ensuring you get the best results from your investment.FAQ

Most Popular Categories Right Now