We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

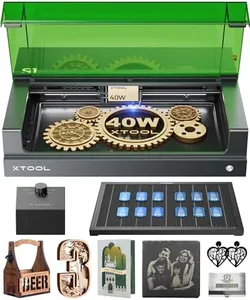

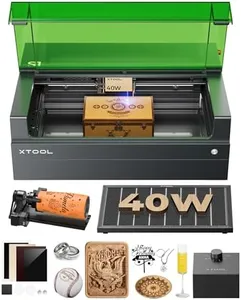

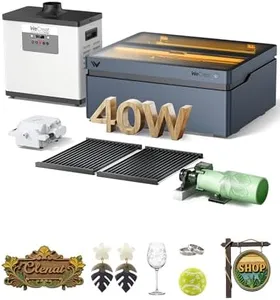

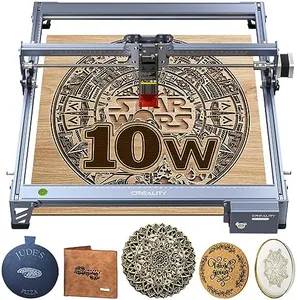

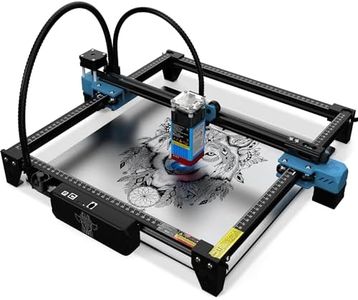

10 Best Laser Leather Cutters 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Laser Leather Cutters

Choosing the right laser leather cutter can be a daunting task, but with the right knowledge, you can find the perfect machine for your needs. Laser leather cutters are versatile tools used for precision cutting and engraving on leather materials. When selecting a laser leather cutter, it's important to consider several key specifications to ensure you get the best fit for your projects. Understanding these specifications will help you make an informed decision and achieve the best results in your leather crafting endeavors.Laser PowerLaser power, measured in watts, determines the cutting and engraving capabilities of the machine. Higher wattage allows for deeper cuts and faster processing speeds. For light engraving and thin leather, a lower wattage (20-40W) may suffice. For thicker leather and more intensive cutting tasks, a higher wattage (50-100W or more) is recommended. Consider the thickness and type of leather you will be working with to choose the appropriate laser power.

Cutting AreaThe cutting area is the maximum size of the material that the laser cutter can handle at one time. This is important if you plan to work on larger pieces of leather. Smaller cutting areas (up to 12x8 inches) are suitable for small projects and detailed work, while larger cutting areas (24x18 inches or more) are better for bigger projects and higher production volumes. Assess the typical size of your leather pieces to determine the right cutting area for your needs.

Precision and AccuracyPrecision and accuracy refer to the machine's ability to produce detailed and consistent cuts and engravings. This is crucial for intricate designs and high-quality finishes. Look for specifications like resolution (measured in dots per inch, DPI) and repeatability (measured in millimeters). Higher DPI and lower repeatability values indicate better precision. If your projects require fine details and exact measurements, prioritize machines with higher precision and accuracy.

SpeedSpeed refers to how quickly the laser cutter can complete a task. This includes both cutting speed and engraving speed, usually measured in millimeters per second (mm/s). Faster speeds can increase productivity, especially for larger projects or batch production. However, higher speeds may sometimes compromise precision. Balance your need for speed with the level of detail required in your work to choose the right machine.

Software CompatibilitySoftware compatibility is important because it determines how you will design and control your laser cutter. Most laser cutters come with their own software, but it's beneficial if the machine is compatible with popular design programs like Adobe Illustrator or CorelDRAW. Ensure the software is user-friendly and meets your design needs. If you are already comfortable with certain design software, look for a laser cutter that supports it to streamline your workflow.

Cooling SystemThe cooling system prevents the laser cutter from overheating during operation. There are different types of cooling systems, such as air-cooled and water-cooled. Water-cooled systems are generally more efficient and suitable for higher power lasers, while air-cooled systems are simpler and may suffice for lower power lasers. Consider the intensity and duration of your cutting tasks to choose the appropriate cooling system to ensure the longevity and reliability of your machine.

Build Quality and DurabilityBuild quality and durability are essential for ensuring that your laser cutter can withstand regular use and last for years. Look for machines made from high-quality materials with sturdy construction. Check for user reviews and manufacturer warranties to gauge the reliability of the machine. If you plan to use the laser cutter frequently or for heavy-duty tasks, prioritize models known for their durability and robust build.

Most Popular Categories Right Now