We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

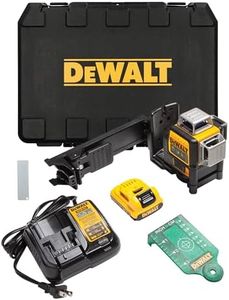

10 Best Laser Levels For Construction 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Laser Levels For Construction

Choosing the right laser level for construction can make a significant difference in the accuracy and efficiency of your work. Laser levels are essential tools for ensuring that your construction projects are level and properly aligned. When selecting a laser level, it's important to consider several key specifications to ensure you get the best fit for your needs. Understanding these specifications will help you make an informed decision and choose a laser level that meets your specific requirements.AccuracyAccuracy refers to how precise the laser level is in projecting a level line. This is crucial because even a small error can lead to significant issues in construction projects. Accuracy is usually measured in millimeters per meter (mm/m) or inches per 100 feet. Higher accuracy levels (e.g., ±1 mm/m) are ideal for tasks that require precise measurements, such as interior finishing or cabinetry. For general construction work, a slightly lower accuracy (e.g., ±3 mm/m) may be sufficient. Choose the accuracy level based on the precision required for your specific tasks.

RangeThe range of a laser level indicates the maximum distance over which it can project a visible line. This is important for determining how far you can work from the laser level while still seeing the line clearly. Ranges can vary from 30 feet to over 1000 feet, depending on the model. For indoor projects or small construction sites, a shorter range (up to 100 feet) may be adequate. For larger outdoor projects, such as site grading or road construction, a longer range (300 feet or more) is necessary. Consider the size of your work area when choosing the range.

Beam TypeLaser levels can project different types of beams, including single-line, cross-line, and rotary beams. Single-line lasers project a single horizontal or vertical line, which is useful for basic leveling tasks. Cross-line lasers project both horizontal and vertical lines, forming a cross, which is helpful for aligning tiles, windows, and doors. Rotary lasers project a 360-degree level line around a room or site, making them ideal for large-scale construction projects. Choose the beam type based on the complexity and scale of your projects.

Self-LevelingSelf-leveling laser levels automatically adjust to ensure the laser line is perfectly level, even if the tool is placed on an uneven surface. This feature is important because it saves time and increases accuracy. Self-leveling lasers typically have a range within which they can adjust themselves, such as ±4 degrees. For most construction tasks, a self-leveling laser is highly recommended as it reduces the need for manual adjustments and ensures consistent accuracy.

DurabilityDurability refers to the laser level's ability to withstand tough construction environments. This includes resistance to dust, water, and impacts. Durability is important because construction sites can be harsh, and a durable laser level will last longer and perform reliably. Look for laser levels with an IP rating (Ingress Protection) that indicates their resistance to dust and water. For example, an IP54 rating means the laser level is protected against dust and water splashes. Choose a durable model if you work in challenging conditions.

Power SourceLaser levels can be powered by batteries or through a direct power source. Battery-powered laser levels offer portability and are convenient for use in areas without access to electricity. However, they require regular battery changes or recharging. Models with rechargeable batteries can be more cost-effective in the long run. Direct power source models provide continuous operation without the need for battery changes but are less portable. Consider your work environment and the availability of power sources when choosing the power option.

Most Popular Categories Right Now