10 Best Manometers 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

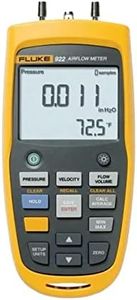

Fluke 922/Kit Airflow Meter Kit

Most important from

19 reviews

The Fluke 922/Kit Airflow Meter Kit is a versatile tool well-suited for HVAC professionals and technicians who need to measure airflow and pressure with precision. One of its standout features is the bright, backlit display, making it easy to read in various lighting conditions, which is quite handy when working in less than ideal environments. It offers a high level of accuracy with a resolution down to 0.001 in H2O, ensuring you get precise measurements to optimize airflow and pressure systems effectively.

Another significant advantage is its ability to provide both differential and static pressure readings along with air velocity and flow metrics. This multifunctionality can save time and space, as technicians won’t need multiple devices to complete their tasks. The user-defined duct shape and size feature enhances accuracy further, allowing for tailored measurements that suit specific applications.

The Fluke 922 is also battery-powered, which is convenient, but users should keep in mind that it requires four AAA batteries. While these batteries are included, it’s essential to ensure you have replacements handy for continuous use.

Most important from

19 reviews

Fluke 922 Airflow Micromanometer with Bright Backlit Display, +/- 0.6 psi Pressure, 16000 fpm Velocity, 99999 cfm Volume

Most important from

28 reviews

The Fluke 922 Airflow Micromanometer is designed primarily for HVAC professionals and building managers who need to measure pressure differences, airflow velocity, and volume accurately. It covers a useful pressure range with ±0.6 psi accuracy, which is solid for typical HVAC tasks. The bright 3.5-inch backlit display and color-coded hoses make reading measurements easier, even in dim environments.

Its ability to measure differential pressure, air velocity up to 16,000 fpm, and volume flow up to 99,999 cfm suits a variety of ventilation and airflow checks. The device is lightweight and built with sturdy plastic, offering good portability and durability. Additional features like automatic frequency control and user-defined duct sizes help improve measurement accuracy and speed up testing. However, as a specialized tool, it might be more than what casual users need, and the price could be higher compared to simpler manometers.

The 2-year warranty adds confidence in its build quality. For those who require reliable, precise airflow and pressure measurements for HVAC maintenance or building performance, the Fluke 922 provides an excellent balance of accuracy, ease of use, and advanced features.

Most important from

28 reviews

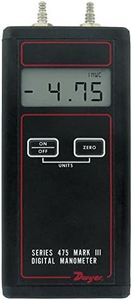

Dwyer® Handheld Digital Manometer, 475-3-FM, 0-200" w.c. (49.82 kPa)

Most important from

74 reviews

The Dwyer Handheld Digital Manometer, model 475-3-FM, is a robust and versatile tool for measuring pressure. With a range of 0 to 200 inches of water column (49.82 kPa) and a clear 4-digit LCD display, it offers a good balance of performance and ease of use. The build quality is commendable, featuring durable aluminum and rubber materials, ensuring longevity and resilience in various environments.

It operates effectively within a broad temperature range from 0 to 140°F, and can be stored safely between -4 and 176°F, adding to its versatility in different settings. The included accessories, such as rubber tubing, a 9V battery, and a custom case, enhance its convenience and readiness for immediate use. Potential users should note that it uses barbed connections, which may require specific tubing sizes (1/8 inches).

Most important from

74 reviews

Buying Guide for the Best Manometers

Choosing the right manometer, a device used to measure pressure, is crucial for ensuring accurate readings and optimal performance in various applications. Whether you're using it for industrial purposes, HVAC systems, or laboratory experiments, understanding the key specifications will help you select the best manometer for your needs. Here are the essential specs to consider and how to navigate them.FAQ

Most Popular Categories Right Now