10 Best Metal Cutting Blade For Grinder 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

50 Pack Cut Off Wheels 4 1/2 inch Thin Metal & Stainless Steel Cutting Wheel, Professional Fast Cutting Disc for Angle Grinder

Most important from

1954 reviews

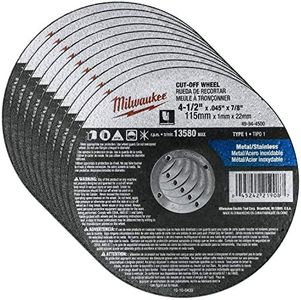

The 50 Pack Cut Off Wheels for Angle Grinders offers a comprehensive solution for those needing a reliable and efficient metal-cutting blade. These wheels boast a 4.5-inch outer diameter and a 7/8-inch arbor size, making them compatible with most standard angle grinders. The blades are designed to operate at up to 13,300 RPM, ensuring fast and effective cutting performance.

The use of aluminum oxide grain enhances the durability and cutting speed, while the double fiberglass mesh reinforcement adds an extra layer of safety and longevity to the blades. With a skinny 0.045-inch thickness, these wheels promise precise, burr-free cuts, making them ideal for working with carbon steel, stainless steel, and various other ferrous metals. This product is also packed with 50 pieces, providing extensive usage before needing a replacement.

On the downside, these cutting discs are coarse grit, which might not be suitable for applications requiring finer finishes. Additionally, users must adhere to safety precautions due to the high operating speeds and potential hazards associated with metal cutting. Given the bulk pack and its specifications, this product is particularly beneficial for professionals or frequent users who need a reliable and efficient solution for cutting metal materials.

Most important from

1954 reviews

DEWALT 4-1/2 Inch Cut-Off Wheel, Angle Grinder Cutting Disc, General Purpose, 5-Pack (DW8062B5)

Most important from

16124 reviews

The DEWALT 4-1/2 Inch Cut-Off Wheel is a reliable option for those needing a general-purpose metal-cutting blade for grinders. This product excels in durability and versatility, thanks to its Temper Point grains, which are designed to last 50% longer than standard wheels. The medium-grit aluminum oxide material is strong enough to cut through various metals, including carbon steel, stainless steel, and nickel-based alloys.

The thin wheel design and high-grain concentration allow for fast and aggressive cutting, making it highly efficient for tasks involving steel, angle iron, pipe, tubing, and rebar. Another notable feature is the dual fiberglass sheets that enhance the wheel's strength and reduce breakage, ensuring safer and more reliable usage.

It is designed for use with specific DEWALT grinder models, such as the DCG416B, limiting its compatibility with other brands. The product dimensions (4.5 inches in diameter) and arbor size (7/8 inch) might also not fit all grinder types, so it's crucial to check compatibility with your specific tool. The DEWALT DW8062B5 pack is a solid choice for those who need durable and versatile cutting wheels for various metalworking tasks.

Most important from

16124 reviews

EZARC Cut Off Wheels 25 Pack, 3” x 1/16” x 3/8” Cutting Wheel, Metal & Stainless Steel Cutting Disc for Die Grinder

Most important from

1716 reviews

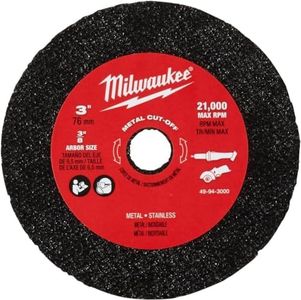

The EZARC Cut Off Wheels come in a pack of 25, each with a 3-inch diameter, 1/16-inch thickness, and a 3/8-inch arbor size. Made from iridium-plated white corundum, these discs offer exceptional durability, boasting twice the lifespan of typical cutting wheels. This makes them a cost-effective choice for those who frequently engage in metal cutting tasks.

The ultra-thin 1/16-inch design ensures fast, precise cuts with minimal burrs, reducing the need for additional finishing work and minimizing material waste. These discs are versatile, capable of cutting through carbon steel, stainless steel, iron, copper, and various other ferrous metals, which is ideal for diverse metalworking projects. They are compatible with all 3-inch die grinders that operate at speeds up to 25,000 RPM, making them suitable for high-speed applications.

Safety is also a priority, as these discs comply with international safety standards such as EN 12413 and ASM07, though it's essential to wear appropriate protective gear and not exceed the recommended speed during use. On the downside, the ultra-thin design, while beneficial for precision, might make these discs more prone to breaking under excessive pressure or misuse. Additionally, for users requiring blades for larger grinders, these 3-inch discs might not suffice. The EZARC Cut Off Wheels are an excellent choice for those in need of durable, precise, and versatile metal-cutting discs for small to medium-sized projects, particularly if used with a die grinder.

Most important from

1716 reviews

Buying Guide for the Best Metal Cutting Blade For Grinder

Choosing the right metal-cutting blade for your grinder is crucial for achieving clean, precise cuts and ensuring your safety. The right blade can make your work easier, faster, and more efficient. When selecting a blade, consider the type of metal you will be cutting, the thickness of the material, and the specific requirements of your project. Understanding the key specifications of metal-cutting blades will help you make an informed decision and select the best blade for your needs.FAQ

Most Popular Categories Right Now