10 Best Pipe Wrenches 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

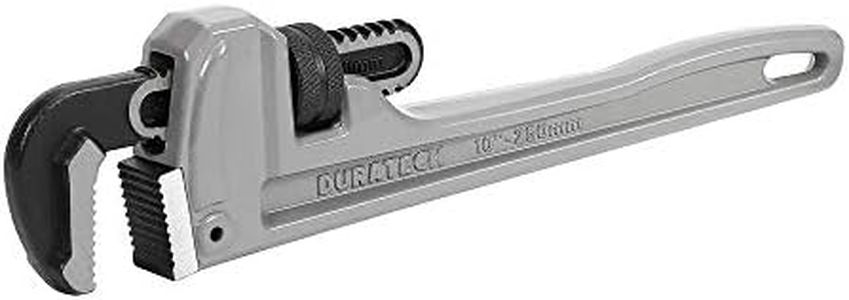

DURATECH 10-inch Heavy Duty Aluminum Straight Pipe Wrench, Adjustable Plumbing Wrench, Drop Forged, Exceed GGG standard

The DURATECH 10-inch Heavy Duty Aluminum Straight Pipe Wrench stands out for its light weight, being nearly 40% lighter than equivalent steel models. This makes it easier to handle during prolonged use or when working in awkward positions. The aluminum material also ensures durability and a long lifespan, while the drop-forged, heat-treated jaw resists breaking or distortion, providing reliable strength for various tasks.

Its slim profile and 10-inch size make it ideal for working in tight spaces or at difficult angles, which is a great advantage for plumbing work. The adjustable, non-stick knurled adjustment nut and self-cleaning threads make it user-friendly, promoting quick adjustments and minimal maintenance. The I-beam handle design offers excellent weight distribution, adding to the comfort and ease of use during operation. This handle also features a hanging hole for convenient storage.

However, while the wrench is versatile and strong, it may not be suitable for very large piping tasks due to its 10-inch size. Also, the aluminum construction, while sturdy, might not be as robust as high-end steel wrenches for extreme heavy-duty work. This tool is excellent for home improvement enthusiasts, DIYers, and professional plumbers who need a reliable, lightweight option for general pipe-related repairs.

RIDGID 31110 Model 836 Aluminum Straight 36" Plumbing Pipe Wrench, Silver, Made In The USA

Most important from

1464 reviews

The RIDGID 31110 Model 836 is a 36-inch aluminum straight pipe wrench designed for professional use, making it an excellent choice for plumbing tasks. One of its standout features is its lightweight design, weighing only 11 lbs, which is about 40% lighter than traditional heavy-duty models. This makes it easier to handle and reduces fatigue during extended use. The full-floating forged alloy steel hook jaws provide impressive gripping power, ensuring efficient pipe adjustments and reliability in various pipe work scenarios. Additionally, the wrench is equipped with self-cleaning threads and parts that are easy to replace, enhancing its usability and maintenance over time.

The construction quality is robust, as it combines aluminum with alloy steel, providing durability without compromising weight. However, users might find that the aluminum body can be less resilient than heavier steel alternatives in extremely demanding tasks. While its lightweight nature is a significant advantage for ease of use, some professionals may prefer the added heft of a steel wrench for specific applications.

On the downside, the 36-inch length, while beneficial for larger pipes, may be cumbersome in tighter spaces. Since this wrench is designed for professional use, beginners may need some time to get accustomed to its handling and operation.

Most important from

1464 reviews

KARRYTON 48 Inch Aluminum Pipe Wrench, 8"/200mm Adjustable Jaw Capacity, Heavy Duty Straight Handle Plumbing Wrenches Plumbers Tool, Exceed the Standard GGG (48-INCH)

Most important from

208 reviews

The KARRYTON 48 Inch Aluminum Pipe Wrench is a robust tool, specifically designed for plumbing and other mechanical tasks. With an adjustable jaw capacity of up to 8 inches, it can handle pipe diameters from 2 to 6 inches, making it ideal for a wide range of applications including household plumbing, vehicle maintenance, and construction. One of its standout features is the aluminum I-beam handle, which is notably lighter than traditional cast iron options, reducing user fatigue during prolonged use. Additionally, the anti-rust coating ensures durability, while the included gloves provide an extra layer of safety during operation.

The jaw material made from Chromium-Molybdenum steel adds to its strength, ensuring that it maintains a firm grip on pipes without slipping, thanks to its V-shaped design and thirty-degree wave teeth. This design is particularly useful for clamping onto various objects, enhancing its versatility.

There are a few drawbacks to consider. Although the aluminum construction makes it lighter, some users might prefer the solid feel of cast iron for heavy-duty tasks. At nearly 8 kilograms, it can still be cumbersome for some. The availability and quality control can vary, which may affect user experience.

Most important from

208 reviews

Buying Guide for the Best Pipe Wrenches

When it comes to choosing the right pipe wrench, it's important to consider the specific needs of your project. Pipe wrenches are essential tools for gripping and turning pipes and fittings, and selecting the right one can make your work more efficient and effective. Understanding the key specifications will help you make an informed decision and ensure you have the right tool for the job.FAQ

Most Popular Categories Right Now