10 Best Router Bit For Flattening Slabs 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

BINSTAK CNC Spoilboard Surfacing Router Bit,1/2 Inch Shank 3 Inch Cutting Diameter, 2+2 Carbide Inserts Slab Flattening Router Bit Planer Bit for Wood Spoil Board Planing

The BINSTAK CNC Spoilboard Surfacing Router Bit is designed for those looking to flatten wooden slabs or surfaces efficiently. With its 1/2 inch shank and a cutting diameter of 3 inches, this router bit is versatile enough for various wood types, including softwoods, hardwoods, and even engineered materials like MDF and laminate. One standout feature is the 2+2 carbide inserts that enhance cutting balance and surface smoothness, making it a great option for users who value precision in their work.

The industrial-grade construction, featuring a super-strength steel body and anti-kickback design, adds an element of safety and durability, which is crucial for both beginners and experienced woodworkers. The cost-effective nature of the bit is also a highlight; since it uses replaceable 4-sided inserts, users can simply rotate or replace the inserts rather than purchasing an entirely new bit when one edge wears out. This can lead to significant savings over time.

The router bit does have some limitations. While it works well on various materials, those who primarily work with very dense or tough woods might find that they need to exert more pressure or make slower passes to achieve the desired finish. Additionally, the necessity of using a screwdriver to switch out the carbide edges might not appeal to everyone, as some may prefer a more straightforward replacement process.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!BINSTAK CNC Spoilboard Surfacing Router Bit 1/4" Shank, Slab Flattening Router Bit with 1-3/8" Cutting Diameter, 2+2 Flutes Insert Carbide Wood Planer Router Bits, Planing Bit for Woodworking

The BINSTAK CNC Spoilboard Surfacing Router Bit is a solid choice for anyone looking to flatten wood slabs efficiently. With a 1/4" shank and a cutting diameter of 1-3/8", it’s compatible with various routers, including CNC and handheld models, making it versatile for different woodworking projects. One of its main strengths is the 2+2 insert design, which provides a balanced operation and smoother surface finish, making it ideal for achieving that polished look on both soft and hard woods, as well as materials like MDF and acrylic.

The use of solid carbide inserts is another highlight, offering a cost-effective solution since each insert has four usable edges, allowing users to simply replace the worn-out edges instead of the entire bit. This can lead to significant savings over time compared to traditional bits that require complete replacement. The industrial-grade steel body and anti-kickback design enhance safety and durability, making it suitable for heavy-duty use.

This router bit meets the needs of woodworkers looking for an efficient and cost-effective tool for flattening slabs but may not be the best fit for those with specific router requirements or preferences for heavier bits.

Customer Highlights

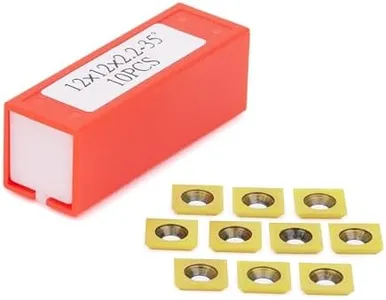

A summary of real customer reviews to highlight what shoppers are saying!SICWOOD Slab Flattening Router Bits 1/2 Shank, 2-3/8”Cut Dia, 12*12*1.5mm Insert, CNC Spoilboard Surfacing Router Bits, Planing Router Bits, for Flycutter/ Slab Leveler/ Rabbeting

The SICWOOD Slab Flattening Router Bit is well-suited for individuals looking to achieve precision in flattening slabs. It features a 1/2-inch shank and a 2-3/8-inch cut diameter, making it suitable for a wide range of projects. The use of premium C2 carbide inserts ensures sharpness and durability, while the tungsten steel body supports robust performance and effective chip evacuation.

This design also contributes to a smooth finish with minimal run-out, thanks to advanced grinding processes that enhance blade strength and hardness. Another advantage is its cost-effectiveness; the replaceable cutters extend the lifespan of the tool, reducing long-term expenses as you only need to purchase new inserts when necessary.

It’s versatile enough to handle various materials including solid wood, density board, laminate, and more, although it is not designed for cutting metal or non-wood materials. This router bit can be used with CNC machines, hand-held, and table-mounted portable routers, making it a flexible choice for different setups. Weighing 0.29 kilograms and with its sturdy build, it is a heavy-duty option that promises long-lasting service, provided it's used within its specified limits.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Buying Guide for the Best Router Bit For Flattening Slabs

When it comes to picking the right router bit for flattening slabs, it's important to understand that not all router bits are created equal. The right choice will depend on the type of wood you're working with, the size of the slab, and the finish you desire. By understanding the key specifications and how they impact performance, you can make an informed decision that will help you achieve the best results for your project.FAQ

Most Popular Categories Right Now