10 Best Scroll Saw Blade Types 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

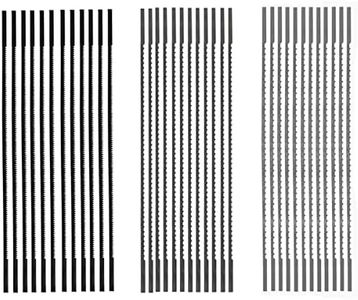

FOXBC 5-Inch Scroll Saw Blade Pin End Replacement for Wen 3921 3923, Dremel, Craftsman, Penn State, Delta, Ryobi and All 15in.and 16in.Scroll Saw For Wood, High Carbon Steel - 48 Pack

Most important from

1459 reviews

The FOXBC 5-Inch Scroll Saw Blade Pin End Replacement pack is a highly versatile option suitable for a wide range of scroll saw brands including WEN, Dremel, Delta, and Ryobi. This 48-pack set includes 12 blades each with different tooth counts (10 TPI, 15 TPI, 18 TPI, 24 TPI), making it adaptable for various cutting tasks from wood to plastic and soft metals like copper.

Made from high carbon SK5 Japanese steel, these blades are robust and offer increased durability and corrosion resistance. Installation is straightforward and the blades are designed to be easy to handle and use, which is beneficial for both beginners and experienced users.

This product is limited to machines that require 5-inch pin end blades, so check your machine compatibility before purchasing. While high carbon steel provides strength, it may not be the best choice for extremely hard materials. This is a reliable and durable choice for those needing versatile and easy-to-use scroll saw blades, especially those working with wood and soft metals.

Most important from

1459 reviews

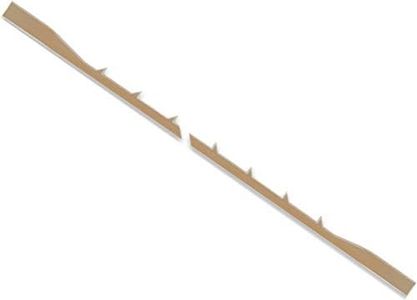

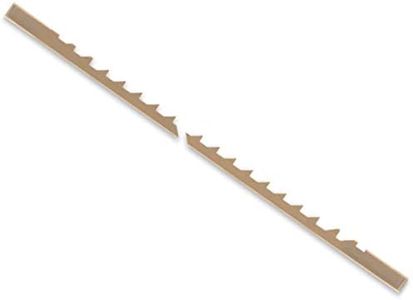

Flying Dutchman Ultra Reverse Five Dozen Scroll Saw Blade Variety Pack

Most important from

614 reviews

The Flying Dutchman Ultra Reverse Five Dozen Scroll Saw Blade Variety Pack offers a set of high-quality blades that are well-suited for precise and clean cuts. Made from top-grade, hardened steel alloy, these blades are durable and maintain their sharpness over time.

The milled design ensures a sharper cutting edge, which can be particularly beneficial for intricate projects. The reverse tooth design helps to minimize splintering on the underside of your work, leading to cleaner finishes.

With a variety of sizes included (#2/0, #1, #3, #5, and #7), this pack provides versatility for different cutting needs. This variety pack is an excellent choice for both hobbyists and professionals seeking reliable and efficient scroll saw blades.

Most important from

614 reviews

Buying Guide for the Best Scroll Saw Blade Types

Choosing the right scroll saw blade is crucial for achieving the best results in your woodworking projects. The blade you select will affect the quality of your cuts, the ease of use, and the types of materials you can work with. Understanding the different types of scroll saw blades and their specifications will help you make an informed decision that suits your specific needs and project requirements.FAQ

Most Popular Categories Right Now