10 Best Small Laser Cutter 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

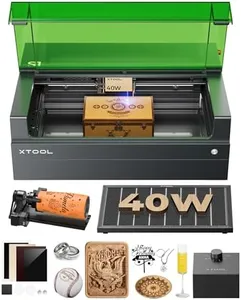

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

Most important from

136 reviews

The xTool S1 40W Laser Cutter and Engraver stands out with its strong 40W laser power, making it capable of cutting through thick materials like 18mm cherry wood in a single pass. This is ideal for users who need a powerful machine for various projects. The large work area of 23.93” x 15.16” offers ample space for big projects, making it suitable for larger items such as door signs or multiple smaller items simultaneously. The engraving speed of up to 600mm/s ensures quick project completion, which is a great time-saver for busy creators.

Precision and resolution are enhanced by xTool’s patented Pin-point Positioning technology, ensuring detailed engravings even on curved surfaces. The device supports a wide range of materials, including wood, metal, and acrylic, expanding the possibilities for creative projects. The software compatibility with xTool Creative Space (XCS) simplifies the design process, even for beginners, thanks to its user-friendly interface and AI-powered design assistance.

The integrated cooling system and Class 1 safety features, like the protective cover and flame sensors, ensure safe operation, making it a secure choice for home use around kids and pets. However, the machine is quite heavy at 79.2 pounds, which might be cumbersome for those who need to move it frequently. Additionally, while the machine is powerful, it may have a learning curve for those new to laser cutting and engraving despite its user-friendly software. The build quality, with an aerospace-grade aluminum frame, promises durability, making it a long-lasting investment. This laser cutter is best suited for hobbyists, small business owners, and DIY enthusiasts who require a powerful, versatile, and reliable machine for their creative projects.

Most important from

136 reviews

WECREAT Vision 20W Laser Engraver, Auto-Lifting for 5.5" Material, Smart Camera for Easiest Positioning, 600mm/s Speed, Laser Engraving Machine for Tumblers Metal Wood Acrylic DIY Craft Gifts Making

Most important from

57 reviews

The WECREAT Vision 20W Laser Engraver is a versatile tool designed for precision engraving and cutting across various materials like wood, acrylic, and metal. The 20W laser power allows for accurate cuts and engravings with a precision of 0.01mm, making it suitable for intricate designs. The work area size, adjustable from 1mm to 140mm due to its auto-lifting feature, is versatile and eliminates the need for manual adjustments, making the process more efficient and user-friendly.

The intelligent air assist system ensures cleaner cuts by reducing burn marks, which is beneficial for users looking for high-quality finishes. It can handle a variety of materials, making it adaptable for different projects, and the rotary system further adds to its versatility by enabling cylindrical engraving. The built-in smart HD camera and quick view matrix simplify design positioning and workflow, which is especially helpful for beginners. The software compatibility with both proprietary software and Lightburn expands its usability for various users.

One of its major strengths is the emphasis on safety, with features like an enclosed design and automatic stops when the lid is opened, making it safe for home use. However, the machine is relatively heavy at 65.4 pounds, which might be a drawback for those needing portability. While it ranks reasonably well in its category, it is not the top performer, indicating that there might be other competitive options available. This laser engraver is well-suited for both hobbyists and professionals looking for a reliable, safe, and versatile machine for various engraving and cutting projects.

Most important from

57 reviews

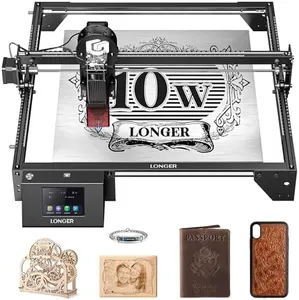

LONGER Laser Engraver Ray5 10W, 60W DIY Laser Cutter and Laser Engraving Machine with 3.5" Touch Screen,0.06mm Laser Spot 10000mm/min, Offline Usage CNC Laser Engravers for Wood Metal Acrylic Glass

Most important from

265 reviews

The LONGER Laser Engraver Ray5 10W is a high-performance small laser cutter that stands out with its 10W laser power, making it capable of cutting through materials like wood up to 0.8 inches thick and acrylic up to 1.2 inches. Its dual-beam technology ensures high precision with a fine laser point of 0.06mm, achieving detailed engraving at speeds up to 10,000mm/min. The large 400x400mm work area allows for versatile project sizes, and the machine supports various connection methods including USB, WiFi, and TF card, along with compatibility with popular software like LaserGRBL and LightBurn.

Safety is prioritized with features like an emergency stop, motion protection, heat protection, and a hidden cooling system, along with a protective cover and safety goggles. The machine's weight of 9.63 pounds and its dimensions may require a dedicated workspace. Additionally, while the device offers offline usability, setting it up for first-time users might need careful attention despite the included setup guides and tools.

Suitable for hobbyists and small business owners, the Ray5's versatility extends to materials such as stainless steel, glass, cotton cloth, leather, and more. It is a reliable option for those looking to invest in a capable and safe laser engraver for various DIY projects.

Most important from

265 reviews

Buying Guide for the Best Small Laser Cutter

Choosing the right small laser cutter can be a game-changer for your projects, whether you're a hobbyist, a small business owner, or a professional. The key to making the best choice is understanding the various specifications and how they align with your specific needs. By focusing on the most important specs, you can ensure that you select a laser cutter that will deliver the performance and reliability you require.FAQ

Most Popular Categories Right Now