We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

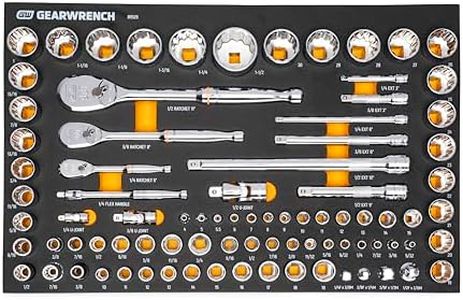

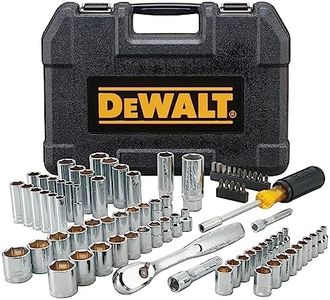

10 Best Socket Sets For Mechanics 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Socket Sets For Mechanics

Choosing the right socket set for mechanics can make a significant difference in the efficiency and ease of your work. A good socket set should be durable, versatile, and suited to the specific tasks you need to perform. When selecting a socket set, consider the types of vehicles or machinery you will be working on, the range of sizes you need, and the quality of the materials. Here are some key specifications to consider when choosing a socket set for mechanics.MaterialThe material of the socket set is crucial because it determines the durability and strength of the tools. Most high-quality socket sets are made from chrome vanadium steel, which is known for its toughness and resistance to wear and tear. Some sets may also be made from chrome molybdenum, which is even stronger and more durable. For general use, chrome vanadium is usually sufficient, but if you need extra strength for heavy-duty tasks, consider chrome molybdenum.

Drive SizeDrive size refers to the size of the square drive that fits into the ratchet handle. Common drive sizes include 1/4 inch, 3/8 inch, and 1/2 inch. The 1/4 inch drive is suitable for lighter tasks and tight spaces, the 3/8 inch drive is versatile and good for most general tasks, and the 1/2 inch drive is ideal for heavy-duty work. Choose a drive size based on the type of work you will be doing most frequently.

Socket SizesSocket sizes are measured in both metric and SAE (Society of Automotive Engineers) units. Metric sizes are measured in millimeters, while SAE sizes are measured in inches. It's important to have a range of sizes to cover different bolts and nuts. For versatility, look for a set that includes both metric and SAE sizes. Consider the specific sizes you will need based on the vehicles or machinery you work on.

Point ConfigurationSockets come in different point configurations, such as 6-point and 12-point. A 6-point socket has six points of contact with the bolt or nut, providing a more secure grip and reducing the risk of rounding off the corners. A 12-point socket has twelve points of contact, making it easier to fit onto fasteners in tight spaces. For most applications, a 6-point socket is preferred for its better grip, but a 12-point socket can be useful for accessibility.

FinishThe finish of the socket set affects its resistance to corrosion and ease of cleaning. A polished chrome finish is common and provides good resistance to rust and corrosion, as well as a smooth surface that is easy to wipe clean. Some sets may have a black oxide or phosphate finish, which also offers good corrosion resistance and a non-slip surface. Choose a finish that suits your working environment and maintenance preferences.

Case and OrganizationA good socket set should come with a sturdy case that keeps the sockets organized and easy to transport. Look for a case with clearly labeled slots for each socket size, which helps you quickly find the right tool and ensures that you don't lose any pieces. A well-organized case can save you time and frustration on the job.

Most Popular Categories Right Now