10 Best Soda Blaster 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

LE LEMATEC Portable Sandblaster Gun Kit, Air Compressor Sand Blaster, Paint & Rust Remover, Abrasive Media & Soda Blaster for Metal, Wood, Automotive & DIY Surface Prep, AS118-2C

Most important from

8674 reviews

The LE LEMATEC Portable Sandblaster Gun Kit (AS118-2C) is a versatile and efficient tool for various surface preparation tasks. Its ability to operate at a high blast pressure of up to 120 PSI ensures powerful and consistent cleaning performance, suitable for removing rust and paint from metal and wood surfaces. The durable ceramic nozzle contributes to smooth media flow and long-lasting use, which is beneficial for users with extensive projects.

The kit's lightweight and portable design make it easy to handle, enhancing its appeal for detailed and long tasks. Additionally, it supports various abrasive media, including soda, sand, and walnut shells, adding to its versatility for different applications such as auto body prep, crafting, and glass etching projects. Setup is straightforward, with no complicated adjustments, making it user-friendly even for those with minimal experience in sandblasting.

Maintenance is also simple, helping prevent media buildup and ensuring hassle-free operation. The product does not specify the hopper capacity, which may be a consideration for users needing to blast large surfaces without frequent refills. The need for an external air compressor can be a limitation if the user does not already own one or if they have limited space. The LE LEMATEC Portable Sandblaster Gun Kit is a strong contender for DIY enthusiasts and professionals alike who seek an efficient and reliable soda-blasting tool.

Most important from

8674 reviews

LE LEMATEC Sand Blaster Gun Kit for Air Compressor, Portable Abrasive Media Blaster for Cleaning, Paint & Rust Removal, Works with Aluminum, Sand, Walnut, & Soda, Ideal for Metal & Wood, AS118 Blue

The LE LEMATEC Sand Blaster Gun Kit is a versatile tool designed for both professionals and DIY enthusiasts, making it ideal for a variety of tasks such as rust and paint removal, and detailed projects like furniture restoration and engine maintenance. It operates within a 90-150 PSI range with a 4.0 CFM requirement, which is powerful enough for tough jobs while being gentle for delicate surfaces like wood. The inclusion of a durable ceramic nozzle ensures longevity and efficient performance.

Its lightweight and ergonomic design, weighing only 1.3 pounds, makes it portable and reduces user fatigue during extended use. The kit's support for multiple media types, including eco-friendly options, enhances its flexibility. Despite its compact form, it is highly effective on various materials, including metal, wood, and glass, making it suitable for both commercial and residential use.

The product is backed by positive customer reviews (4.2 out of 5 stars) and ranks highly in tools and home improvement categories. Users should ensure their air compressor meets the specified requirements to maximize its performance. This sand blaster gun kit offers a good balance of power, versatility, and user-friendly features.

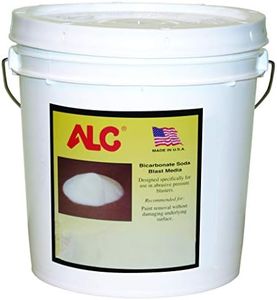

ALC Pressure Blaster,150 lb Capacity, Black, Large

The ALC Pressure Blaster is designed for those needing a reliable soda-blasting tool for various cleaning or surface preparation tasks. With a large 150 lb capacity, it can hold a significant amount of abrasives, allowing for longer work sessions before needing a refill. This can be especially beneficial for larger projects, making it a great choice for DIY enthusiasts or professionals who frequently work on big jobs. The blasting pressure is suitable for effective cleaning without being too aggressive, which is important for preserving the integrity of surfaces.

Portability is a noteworthy feature, although the 68-pound weight may be a consideration for some users. Its dimensions suggest it is relatively compact, but moving it around may require some effort. The build quality is reinforced by its manufacturer, ALC, which is known for durable products made in the United States. This ensures longevity and reliability, which are vital in demanding environments.

Potential drawbacks include the need for a compatible air compressor, which isn't included. Users should check their existing equipment to ensure it meets the required specifications for optimal performance. Additionally, the nozzle size may limit the precision or type of blasting tasks it can handle, depending on the user's specific needs. The ALC Pressure Blaster is a strong choice for those seeking a powerful soda-blaster with good capacity and durability. It may be less suitable for users looking for a lightweight or all-in-one solution, but it excels in delivering effective blasting for larger cleaning projects.

Buying Guide for the Best Soda Blaster

Choosing the right soda blaster can make a significant difference in the efficiency and quality of your cleaning or surface preparation tasks. Soda blasters use baking soda as the blasting medium, which is gentle enough to clean surfaces without causing damage. When selecting a soda blaster, it's important to consider several key specifications to ensure you get the best fit for your needs. Understanding these specs will help you make an informed decision and achieve the best results for your projects.FAQ

Most Popular Categories Right Now