10 Best Spark Plug Wires 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

JDMSPEED High Performance Spark Plug Ignition Wire for 2000-2009 Chevy GMC V8

The JDMSPEED High Performance Spark Plug Ignition Wire is specifically designed for the 2000-2009 Chevy GMC V8 models, making it a great fit for vehicle owners looking to replace their ignition wires with a high-quality option. One of the standout features is its 10.2mm spiral wound design, which helps reduce electrical resistance and improve performance. The ultra-low resistance KEVLAR core is another strength, ensuring better conductivity and reliability compared to standard wires. Furthermore, the high-strength silicone boots and sleeve enhance the product's durability, making it suitable for high-temperature conditions commonly experienced in engine compartments.

On the downside, the length of 5.35 inches may not be ideal for every vehicle setup, and users should verify compatibility before purchase. While the one-year warranty provides some peace of mind, it’s relatively short when compared to some other brands that offer longer warranties. Additionally, although the product boasts premium materials, some users might find it slightly pricier compared to basic spark plug wires, which could be a consideration for budget-conscious buyers.

This product is particularly suitable for those who prioritize performance and durability, especially owners of the specified Chevy GMC models seeking a reliable ignition wire replacement. If you're just looking for a basic, budget-friendly option without the need for high performance, consider exploring other alternatives.

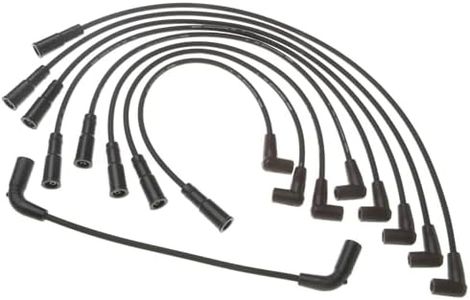

General Motors ACDelco Genuine Parts 19431551 Sparkplug Wire Kit

The ACDelco Genuine Parts 19431551 Sparkplug Wire Kit is a solid choice for anyone needing spark plug wires specifically for General Motors vehicles. Its durability is a key strength, allowing it to handle high voltage pulses without damage, which is essential for reliable engine performance. Designed and tested for GM vehicles, this kit ensures a precise fit, making installation straightforward for both professionals and DIY enthusiasts. The materials used, namely PVC, contribute to its resilience and longevity.

The product is limited to GM vehicles, which may not be suitable for users with other makes. While the kit provides a good warranty, the recommendation for installation through a GM dealer or service center could add to the cost, especially for those who prefer doing their own repairs.

This spark plug wire kit is tailored for GM car owners looking for reliability and easy installation. If you're not driving a GM vehicle or prefer DIY installations without the need for professional help, you might want to explore other options.

ACDelco Professional 9748HH Spark Plug Wire Set

Most important from

2310 reviews

The ACDelco Professional 9748HH Spark Plug Wire Set is a high-quality option for those looking to enhance spark delivery and protection in their vehicles. Made with a copper core, these wires offer superior conductivity, which is crucial for maximizing spark efficiency. The wire length and diameter are designed to provide reliable performance and protection, ensuring that the spark reaches the plug effectively.

Additionally, the spark plug distributor boot is made from durable materials that promise a secure fit and a water-tight seal, which is essential for maintaining performance in various driving conditions. The terminal design adds to the product’s strengths by improving spark plug retention and making installation easier, while also offering excellent resistance to corrosion. The insulator employs high dielectric materials, which further enhances protection and durability.

On the downside, this spark plug wire set is specifically designed for UTVs, which may limit its applicability for other types of vehicles. Despite this, its popularity and high customer ratings suggest that it is a reliable and well-received product. Weighing just 1.12 pounds and made in China, the ACDelco Professional 9748HH combines quality materials and thoughtful design to provide a robust solution for spark plug needs. Its high resistance and durability make it a strong contender in the automotive replacement parts market.

Most important from

2310 reviews

Buying Guide for the Best Spark Plug Wires

When it comes to maintaining your vehicle's performance, choosing the right spark plug wires is crucial. Spark plug wires, also known as ignition wires, are responsible for carrying the electrical current from the ignition system to the spark plugs. This current ignites the air-fuel mixture in the engine's cylinders, which is essential for the engine to run smoothly. Selecting the right spark plug wires can improve your vehicle's performance, fuel efficiency, and overall reliability. Here are some key specifications to consider when choosing spark plug wires.FAQ

Most Popular Categories Right Now