We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Stained Glass Making Tools 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Stained Glass Making Tools

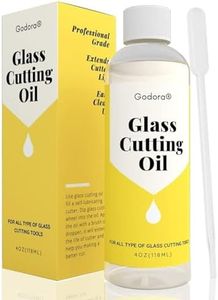

Choosing the right tools for stained glass making is crucial for both beginners and experienced artisans. The right tools can make the process smoother, safer, and more enjoyable. When selecting tools, consider the type of projects you plan to undertake, your skill level, and the specific techniques you want to use. Here are some key specifications to consider when picking stained glass making tools.Glass CutterA glass cutter is a handheld tool used to score the glass before breaking it along the scored line. This tool is essential for creating precise cuts and shapes in your glass pieces. Glass cutters come with different types of cutting heads, such as carbide or steel. Carbide cutters are more durable and provide smoother cuts, making them ideal for frequent use. Steel cutters are less expensive but may need to be replaced more often. Choose a glass cutter that feels comfortable in your hand and suits the frequency and precision of your cutting needs.

Running PliersRunning pliers are used to apply pressure along the score line to break the glass cleanly. They have a curved jaw that helps distribute pressure evenly, reducing the risk of jagged edges. The size and quality of running pliers can vary. Smaller pliers are suitable for delicate, intricate work, while larger pliers are better for breaking thicker glass. Look for pliers with adjustable tension to accommodate different glass thicknesses and ensure a clean break.

Grozing PliersGrozing pliers are used to nibble away small pieces of glass to refine the edges and fit pieces together more precisely. They have serrated jaws that grip the glass securely. The quality of grozing pliers can affect their durability and the precision of your work. Higher-quality pliers will have better grip and control, making them ideal for detailed work. Choose grozing pliers that are comfortable to hold and provide the control you need for your projects.

Soldering IronA soldering iron is used to melt solder, which joins pieces of glass together in stained glass projects. The power and tip size of the soldering iron are important factors. Higher wattage irons heat up faster and maintain a consistent temperature, which is crucial for smooth soldering. Tip size should match the scale of your work; finer tips are better for detailed work, while larger tips are suitable for bigger joints. Choose a soldering iron with adjustable temperature control for versatility in different projects.

GrinderA glass grinder is used to smooth and shape the edges of cut glass pieces. It helps to remove sharp edges and refine the fit of the pieces. Grinders come with different types of grinding bits, such as standard, fine, and coarse. Standard bits are suitable for general use, fine bits for delicate work, and coarse bits for rapid material removal. Consider the size and power of the grinder; larger, more powerful grinders are better for heavy use, while smaller, less powerful grinders are suitable for occasional use. Choose a grinder that matches the scale and frequency of your projects.

Foiling ToolsFoiling tools are used to apply copper foil to the edges of glass pieces before soldering. The width and adhesive quality of the foil are important. Wider foil provides a stronger joint but may be more visible in the finished piece, while narrower foil is less obtrusive but may be less durable. High-quality adhesive ensures the foil stays in place during soldering. Choose foiling tools that are easy to handle and provide a consistent application of foil to suit your project's needs.

Most Popular Categories Right Now