We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Straight Edge For Cutting Glass 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Straight Edge For Cutting Glass

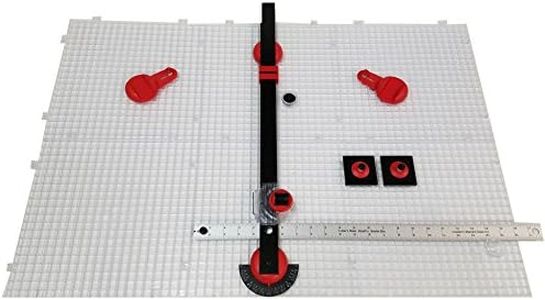

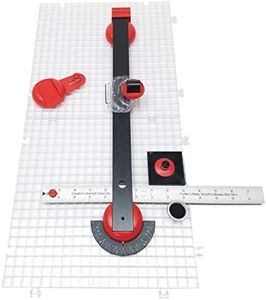

Choosing the right straight edge for cutting glass is crucial for achieving precise and clean cuts. A straight edge is a tool that helps guide your cutting tool along a straight line, ensuring accuracy and consistency. When selecting a straight edge, consider the material, length, thickness, and additional features that can enhance your cutting experience. Understanding these key specifications will help you make an informed decision and find the best fit for your needs.MaterialThe material of the straight edge is important because it affects durability and accuracy. Common materials include aluminum, steel, and plastic. Aluminum is lightweight and resistant to rust, making it a popular choice for many users. Steel is heavier and more durable, providing a solid guide for cutting, but it can be prone to rust if not properly maintained. Plastic is lightweight and affordable but may not be as durable or precise as metal options. Choose a material that balances durability and ease of use based on your cutting frequency and environment.

LengthThe length of the straight edge determines how long of a cut you can make in one pass. Straight edges come in various lengths, typically ranging from 12 inches to 72 inches or more. For small projects or detailed work, a shorter straight edge may be sufficient. For larger sheets of glass or longer cuts, a longer straight edge will be necessary. Consider the size of the glass you typically work with and choose a length that allows you to make clean, continuous cuts without repositioning the straight edge.

ThicknessThickness refers to the width of the straight edge's body. A thicker straight edge provides more stability and is less likely to flex or bend during use, which is important for maintaining accuracy. Thicker straight edges are generally more durable and can withstand more pressure. However, they can also be heavier and more cumbersome to handle. If you need precision and stability, opt for a thicker straight edge. If portability and ease of handling are more important, a thinner straight edge may be more suitable.

Edge TypeThe edge type of the straight edge can affect the quality of your cuts. Some straight edges have a beveled edge, which can help guide the cutting tool more smoothly and reduce the risk of chipping the glass. Others have a flat edge, which provides a solid guide but may not offer the same level of smoothness. Consider the type of cuts you need to make and whether a beveled edge would provide a better result for your specific projects.

Additional FeaturesSome straight edges come with additional features that can enhance their functionality. For example, some models have non-slip backing to prevent the straight edge from moving during use, which can improve accuracy and safety. Others may have measurement markings for added convenience, allowing you to measure and cut in one step. Consider what additional features might be beneficial for your work and choose a straight edge that offers those enhancements.

Most Popular Categories Right Now