We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Strongest Plastic Glue 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Strongest Plastic Glue

When it comes to choosing the strongest plastic glue, it's important to understand that different glues are formulated for different types of plastic and applications. The right glue for your project will depend on the type of plastic you are working with, the conditions the bond will be exposed to, and the strength required. Here are some key specifications to consider when selecting the best plastic glue for your needs.Type of PlasticDifferent plastics have different chemical compositions, which means that not all glues will work on all types of plastic. Common types of plastic include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and acrylonitrile butadiene styrene (ABS). It's important to choose a glue that is specifically formulated to bond with the type of plastic you are working with. Check the product label to ensure compatibility with your plastic type.

Bond StrengthBond strength refers to how strong the adhesive bond will be once the glue has cured. This is crucial for ensuring that the glued parts stay together under stress. Bond strength is usually measured in pounds per square inch (PSI). For light-duty applications, a lower bond strength may be sufficient, while heavy-duty applications will require a higher bond strength. Consider the demands of your project to determine the necessary bond strength.

Curing TimeCuring time is the amount of time it takes for the glue to fully set and reach its maximum strength. This can range from a few minutes to several hours or even days. If you need a quick fix, look for a glue with a shorter curing time. However, for projects where maximum strength is critical, a longer curing time might be acceptable. Balance your need for speed with the strength requirements of your project.

ViscosityViscosity refers to the thickness of the glue. Low-viscosity glues are more liquid and can penetrate small gaps and cracks, making them ideal for tight-fitting parts. High-viscosity glues are thicker and better for filling gaps or bonding uneven surfaces. Choose a viscosity that matches the nature of the surfaces you are bonding. For precise applications, a low-viscosity glue may be best, while for gap-filling, a high-viscosity glue is more suitable.

Water and Temperature ResistanceIf the glued parts will be exposed to water, humidity, or extreme temperatures, it's important to choose a glue that can withstand these conditions. Water-resistant glues are essential for outdoor or marine applications, while temperature-resistant glues are necessary for items that will be exposed to heat or cold. Consider the environment in which the glued item will be used to ensure the glue will hold up under those conditions.

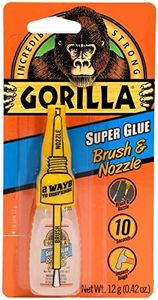

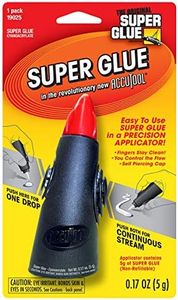

Application MethodThe way the glue is applied can affect the ease and precision of your project. Some glues come in squeeze tubes, while others are applied with brushes or syringes. Choose an application method that suits the size and complexity of your project. For small, detailed work, a precision applicator may be best, while for larger surfaces, a squeeze tube or brush might be more efficient.

Most Popular Categories Right Now