10 Best Truck Brake Rotors 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

WEIZE Front Truck & Tow Brake Kit for Chevy GMC Silverado 11-19 Sierra 2500 3500 HD, CARBON FIBER Ceramic Brake Pads Drilled & Slotted Disc Brake Rotors 2011 2012 2013 2014 2015 2016 2017 2018 2019

The WEIZE Front Truck & Tow Brake Kit is designed specifically for Chevy and GMC trucks from 2011 to 2019, making it a strong option for owners of these vehicles. The kit includes carbon fiber ceramic brake pads and drilled & slotted rotors made from G3000 cast iron. This combination is ideal for trucks that carry heavy loads or tow, as it enhances stopping power and cooling efficiency.

The kit also comes with a 48,000-mile or 4-year warranty, adding peace of mind for long-term use. At 13.98 inches in diameter, the rotors are a significant size, which should fit the specified models well, but users must check the product description and fitment chart to ensure compatibility with their specific drivetrain, body type, and engine size.

One potential drawback is the weight of the kit, which is fairly heavy at 81.4 pounds, possibly making installation a bit cumbersome. Additionally, it’s worth noting that some users may find the price point higher compared to more standard brake kits. However, for those needing enhanced performance for heavy-duty use, this kit could be worth the investment.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Power Stop Brake Kit For 2010-2022 Lexus GX460, 2010-2023 Toyota 4Runner - Front and Rear Z36 Truck & Tow, Drilled and Slotted Brake Rotors, and Carbon Fiber Ceramic Brake Pads Replacement, K5874-36

The Power Stop Brake Kit is a comprehensive solution for those driving 2010-2022 Lexus GX460 and 2010-2023 Toyota 4Runner vehicles. This kit includes both front and rear drilled and slotted brake rotors paired with carbon fiber ceramic brake pads. The material and design are specifically chosen for their durability and performance under stress, making it an excellent choice for trucks, SUVs, and 4x4s, especially those used for towing, hauling, or mountainous terrain.

The zinc plating provides significant protection against rust, which enhances the longevity of the kit. Additionally, the inclusion of high-temp rubberized shims helps in reducing noise during braking, adding to the comfort of the driving experience. Potential buyers should be aware that this kit is heavy, weighing nearly 79 pounds, which may make installation more challenging for those without experience.

The price point might also be higher compared to standard brake kits, but the investment could be justified by its high performance and durability. This brake kit is best suited for individuals who frequently engage in demanding driving conditions or require robust braking performance for their trucks.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!Power Stop K6403-36 Front Truck & Tow Drilled and Slotted Rotors and Z36 Carbon-Fiber Ceramic Brake Pads Brake Kit For Ford F-250 F-350 F-450 4WD 8 Lug

The Power Stop K6403-36 Front Truck & Tow Brake Kit is designed for heavy-duty use, making it a solid choice for Ford F-250, F-350, and F-450 trucks. The rotors are drilled and slotted for improved cooling, which helps prevent brake fade, an important factor for towing and heavy loads. Made from proprietary carbon-fiber ceramic material, the brake pads offer enhanced strength compared to standard ceramics, reducing dust by about 30%, as validated by third-party tests.

This means cleaner wheels and less maintenance. The zinc plating on the rotors provides rust protection, extending their lifespan. Users appreciate the quiet operation due to the high temp rubberized shims that insulate noise. Additionally, the kit includes stainless steel hardware and high-temperature ceramic brake lubricant for ease of installation and durable performance.

On the downside, the product is on the heavier side, weighing around 84.2 pounds, which could be cumbersome during installation. While it’s specifically designed for trucks, it’s essential to confirm fitment for your vehicle before purchase.

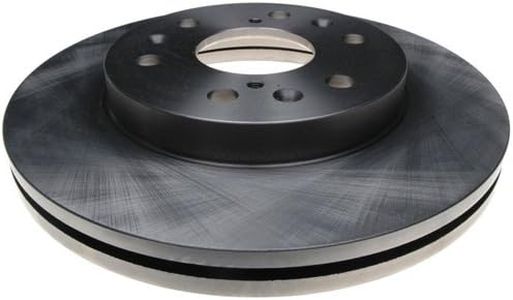

Buying Guide for the Best Truck Brake Rotors

When it comes to picking the right brake rotors for your truck, it's essential to understand the key specifications and how they impact performance, safety, and longevity. Brake rotors are a critical component of your vehicle's braking system, and choosing the right ones can make a significant difference in your driving experience. Here are the key specs you should consider when selecting brake rotors for your truck.FAQ

Most Popular Categories Right Now