10 Best Tungsten Grinder 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

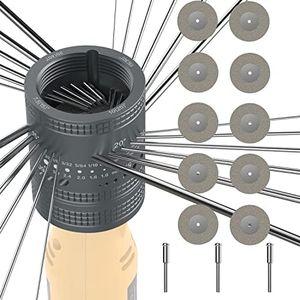

SONNLER Tungsten Electrode Sharpener Grinder For TIG welding, 6 Sizes 10 Angles, TIG Welding Rotary Tool With Flat Grinding Block Cut-Off Slot, 10 Diamond Wheels, 3 CNC Mandrels

Most important from

280 reviews

The SONNLER Tungsten Electrode Sharpener Grinder is a handy tool designed specifically for TIG welding enthusiasts and professionals. One of its standout features is portability; being lightweight and compact makes it easy to use in various settings without the hassle of bulky machinery. This grinder supports multiple tungsten sizes and angles, allowing for precise sharpening, which is essential for achieving optimal welding results. Users appreciate the straightforward operation, as the design allows for quick adjustments without the need for complicated setups, making it accessible even for beginners.

In terms of performance, the SONNLER grinder is effective in enhancing welding productivity. This product suits those who are serious about TIG welding and seek an affordable, portable solution for maintaining their tungsten electrodes effectively.

Most important from

280 reviews

YESWELDER Tungsten Electrode Sharpener Grinder For TIG welding, Handheld Electric, 110V TIG Welding Rotary Tool With Flat Grinding Block Cut-Off Slot, 4 Sizes 3 Angles

Most important from

34 reviews

The YESWELDER Tungsten Electrode Sharpener Grinder is a versatile tool designed for TIG welding, suitable for both beginners and professionals. It offers four common sizes and three different grinding angles (15°, 22.5°, 30°), making it adaptable to various welding needs. The operation is straightforward, with fixed height and hole designs that simplify the grinding process, ensuring safety and efficiency.

The grinder features a durable double-sided diamond wheel that enhances its longevity, reducing the need for frequent replacements. This contributes to consistent, high-quality grinding results over time. Additionally, the grinder has an aluminum alloy body with CNC finishes, ensuring durability and resistance to high temperatures. It includes a dust cover that effectively collects tungsten dust during the grinding process, promoting a cleaner and safer work environment.

However, at nearly 5 pounds, it may not be the most portable option for those who need to move it frequently. The dimensions also suggest it could be a bit bulky for smaller workspaces. Despite these potential drawbacks, its ease of use, reliable performance, and safety features make it a strong candidate for those seeking a comprehensive tungsten grinding solution.

Most important from

34 reviews

DIDUEMEM 8V Tungsten Electrode Sharpener, Cordless Tungsten Grinder for tig welding with Flat Grinding Block, Cut-Off Slot, Multi-Angle & Offsets

Most important from

116 reviews

The DIDUEMEM 8V Tungsten Electrode Sharpener is a professional-grade tool tailored for TIG welding enthusiasts. It features precise angle settings with four preset options (22.5°, 20°, 15°, and 10°) for commonly used electrode sizes, ensuring consistent and accurate sharpening to enhance welding precision. Its compact, cordless design makes it highly portable, ideal for both workshop and on-site tasks, supported by a durable 8V rechargeable battery and a charger compatible with 110-240V outlets, suitable for various regions.

The inclusion of high-quality accessories like double-sided grinding wheels and CNC spindles adds to its durability and longevity. Ease of use is a standout feature, as it requires no setup out of the box and features a single-arm grinding head for easy part replacement, significantly boosting work efficiency. This sharpener is best suited for those needing a reliable, portable, and efficient tool for TIG welding electrode maintenance.

Most important from

116 reviews

Buying Guide for the Best Tungsten Grinder

Choosing the right tungsten grinder is essential for anyone involved in welding, as it ensures precision and quality in your work. A tungsten grinder is used to sharpen tungsten electrodes, which are crucial for creating a stable arc and achieving clean welds. When selecting a tungsten grinder, it's important to consider several key specifications to ensure it meets your needs and enhances your welding performance.FAQ

Most Popular Categories Right Now