We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

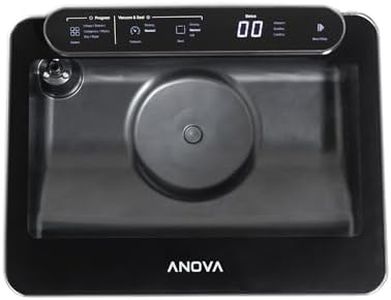

10 Best Vacuum Chambers 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Vacuum Chambers

Choosing the right vacuum chamber can be a crucial decision depending on your specific needs and applications. Vacuum chambers are used in various industries and research fields to create a controlled environment by removing air and other gases. To make an informed decision, you need to understand the key specifications and how they align with your requirements. Here are the main factors to consider when selecting a vacuum chamber.MaterialThe material of the vacuum chamber is important because it affects the chamber's durability, chemical resistance, and ability to achieve and maintain a vacuum. Common materials include stainless steel, aluminum, and glass. Stainless steel is highly durable and resistant to corrosion, making it suitable for most applications. Aluminum is lighter and less expensive but may not be as durable. Glass allows for visual inspection but is more fragile. Choose the material based on the specific requirements of your application, such as the need for chemical resistance or the ability to observe the process inside the chamber.

Size and VolumeThe size and volume of the vacuum chamber determine how much space you have for your experiments or processes. This is crucial because it needs to accommodate your equipment and samples comfortably. Small chambers are suitable for compact setups and small-scale experiments, while larger chambers are necessary for bigger equipment or larger-scale processes. Consider the dimensions of your equipment and the amount of space you need to work efficiently when selecting the size and volume of the chamber.

Vacuum LevelThe vacuum level, or the degree of vacuum that the chamber can achieve, is a critical specification. It is usually measured in terms of pressure, such as Torr or Pascal. There are different levels of vacuum: low vacuum (above 1 Torr), medium vacuum (1 Torr to 10^-3 Torr), high vacuum (10^-3 Torr to 10^-7 Torr), and ultra-high vacuum (below 10^-7 Torr). The required vacuum level depends on your application. For example, basic degassing might only need a low vacuum, while advanced scientific research might require an ultra-high vacuum. Determine the vacuum level needed for your specific application to choose the right chamber.

Pump CompatibilityThe type of vacuum pump you use with the chamber is important because it affects the efficiency and effectiveness of achieving the desired vacuum level. Different pumps, such as rotary vane pumps, diaphragm pumps, and turbomolecular pumps, have varying capabilities and are suitable for different vacuum levels. Ensure that the vacuum chamber you choose is compatible with the type of pump you plan to use. Consider the pump's capacity, maintenance requirements, and how well it integrates with the chamber to achieve optimal performance.

Sealing MechanismThe sealing mechanism of a vacuum chamber is crucial for maintaining the vacuum over time. Common sealing mechanisms include O-rings, gaskets, and metal seals. O-rings are flexible and easy to replace but may not be suitable for high-temperature applications. Gaskets provide a good seal but may require more maintenance. Metal seals offer the best performance for ultra-high vacuum applications but are more expensive and harder to replace. Choose a sealing mechanism that matches the vacuum level and environmental conditions of your application to ensure a reliable seal.

Port ConfigurationThe port configuration refers to the number and type of ports available on the vacuum chamber for connecting various instruments, sensors, and pumps. The right port configuration allows you to set up your equipment efficiently and ensures that you can monitor and control the vacuum environment effectively. Consider the number of ports you need, their sizes, and their positions on the chamber. Ensure that the chamber has enough ports to accommodate all your equipment and that they are conveniently located for your setup.

Most Popular Categories Right Now