10 Best Vinyl Cutting Machines 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Cricut Joy Xtra Smart Cutting Machine, White

Most important from

887 reviews

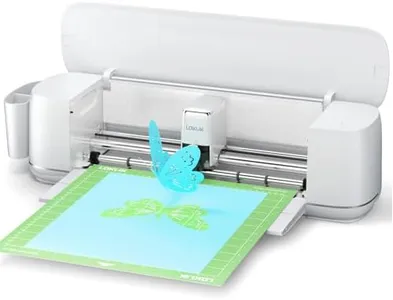

The Cricut Joy Xtra Smart Cutting Machine in white is a compact and versatile tool designed for various crafting projects. One of its key strengths is its ability to work with over 50 different materials, including vinyl, iron-on, and cardstock, making it suitable for a wide range of creative applications. It can handle popular material sizes like US Letter and A4, which is great for users who need to work with these common dimensions.

The machine’s precision in cutting intricate designs, as well as its capability to write, draw, and foil, adds to its appeal for detailed and multifaceted projects. Additionally, it's compatible with home inkjet printers, allowing users to print and cut full-color designs seamlessly. The Cricut Joy Xtra is a user-friendly and versatile option for hobbyists and crafters who value precision and material versatility in their projects.

Most important from

887 reviews

Cricut Maker 3 Smart Cutting Machine - Vinyl Starter Bundle

The Cricut Maker 3 Smart Cutting Machine Vinyl Starter Bundle is a versatile and user-friendly option for both beginners and experienced crafters. One of its main strengths is its exceptional cutting width and cutting force, allowing it to handle a wide range of materials beyond just vinyl, including fabric, leather, and balsa wood. This makes it a great investment for users looking to tackle various projects. Additionally, the cutting speed is notably fast, which can significantly reduce the time spent on large projects.

The bundle also includes useful accessories like a Permanent Vinyl Roll, Transfer Tape, Machine Mats, and a Tool Kit, ensuring you have everything you need to get started right away. The inclusion of 30 digital images and beginner guides is particularly beneficial for new users, providing ample resources to help you learn and create with confidence.

However, there are some drawbacks to consider. The machine's reliance on the Cricut Design Space app for all design tasks could be limiting for some users, especially those who prefer more flexibility in software options. While the app is compatible with iOS, Android, Windows, and Mac, it does require a stable internet connection for full functionality. Additionally, the machine's size and weight (26.5 x 11.63 x 15 inches; 26.01 pounds) might pose storage challenges for those with limited space.

Cricut Explore 3 & Digital Content Library Bundle - Includes 30 images in Design Space App - 2X Faster DIY Cutting Machine for all Crafts, Cuts 100+ Materials Blue

Most important from

474 reviews

The Cricut Explore 3 is a solid choice for anyone looking to dive into vinyl cutting, especially for craft enthusiasts and small business owners. One of its standout features is its ability to cut over 100 materials, including vinyl, cardstock, and even fabric, making it versatile for various projects. The machine operates at impressive speeds, being touted as 2X faster than its predecessors, which can be a huge time-saver for busy crafters. Additionally, the inclusion of Smart Materials allows users to cut larger pieces without a mat, streamlining the crafting process further.

The Bluetooth connectivity and compatibility with the Design Space app enhance user experience, allowing for easy design creation on multiple devices. This makes it accessible for both novice and experienced users, as the app is user-friendly and provides guidance through the crafting process. The digital content library included with the bundle is a nice touch, offering users a head start with 30 images for their projects.

There are a few considerations to keep in mind. The machine's weight (7.3 kg) may make it less portable, which could be a drawback for those looking to take their projects on the go. Furthermore, while it is compatible with various materials, some specialty materials could require additional blades or tools, which could add to the overall cost. Lastly, the requirement for an app may deter those who prefer a more traditional or standalone cutting machine setup.

Most important from

474 reviews

Buying Guide for the Best Vinyl Cutting Machines

Choosing the right vinyl cutting machine can be a game-changer for your crafting or business needs. Whether you're a hobbyist looking to create custom designs or a professional needing precise cuts for large projects, understanding the key specifications of vinyl cutting machines will help you make an informed decision. Here are the essential specs to consider and how to navigate them to find the best fit for your needs.FAQ

Most Popular Categories Right Now