We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Way To Cut Foam Board 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Way To Cut Foam Board

Cutting foam board can be a straightforward task if you have the right tools and techniques. Foam board is a versatile material used in various projects, from school presentations to architectural models. To achieve clean and precise cuts, it's essential to understand the different tools and methods available. This guide will help you navigate the key aspects to consider when cutting foam board, ensuring you get the best results for your specific needs.Cutting ToolsThe tool you use to cut foam board is crucial for achieving clean edges and precise shapes. Common tools include utility knives, X-Acto knives, and hot wire cutters. Utility knives are versatile and can handle thicker boards, while X-Acto knives are great for detailed work. Hot wire cutters provide smooth cuts without compressing the foam. Choose a tool based on the complexity and precision required for your project.

Blade SharpnessA sharp blade is essential for cutting foam board cleanly. Dull blades can tear the foam, resulting in rough edges and an unprofessional finish. Regularly replace or sharpen your blades to maintain cutting efficiency. For most projects, a fresh blade will ensure smooth, precise cuts. If you notice any resistance or tearing, it's time to change the blade.

Cutting SurfaceUsing a proper cutting surface can protect your work area and improve cutting accuracy. A self-healing cutting mat is ideal as it provides a smooth, durable surface that won't damage your blades. Ensure the mat is large enough to accommodate your foam board and allows for easy maneuvering of your cutting tool. Avoid cutting on hard surfaces like tables or floors, as this can dull your blade and damage the surface.

Cutting TechniqueThe technique you use can significantly impact the quality of your cuts. For straight cuts, use a metal ruler or straight edge to guide your blade. Apply even pressure and make multiple light passes rather than a single deep cut to avoid compressing the foam. For curved or intricate cuts, take your time and follow the lines carefully. Practice on scrap pieces to refine your technique before working on your final project.

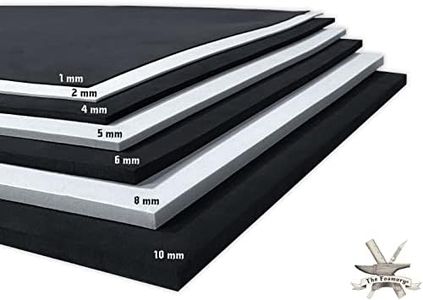

Board ThicknessFoam boards come in various thicknesses, typically ranging from 3mm to 10mm. Thicker boards provide more rigidity and are suitable for larger projects, while thinner boards are easier to cut and better for detailed work. Consider the requirements of your project when selecting the board thickness. For example, a 5mm board is a good all-around choice for most applications, offering a balance between ease of cutting and structural integrity.

Safety PrecautionsSafety should always be a priority when cutting foam board. Use a cutting tool with a comfortable grip to reduce hand fatigue and improve control. Always cut away from your body and keep your fingers clear of the blade's path. Wear protective gloves if necessary, and ensure your work area is well-lit and free of obstructions. Proper safety measures will help prevent accidents and ensure a smooth cutting process.

Most Popular Categories Right Now