We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

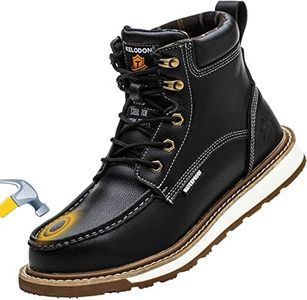

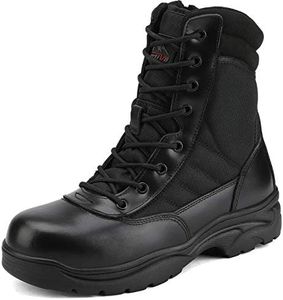

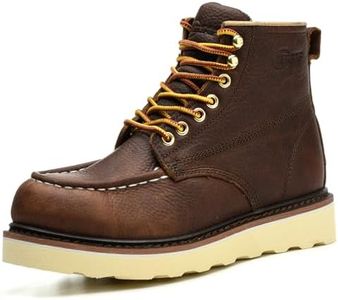

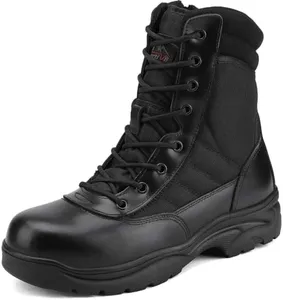

10 Best Welding Boots 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Welding Boots

Choosing the right welding boots is crucial for ensuring safety and comfort while working in environments where welding is performed. Welding boots are designed to protect your feet from extreme heat, sparks, and potential injuries. When selecting welding boots, it's important to consider several key specifications to ensure you get the best fit for your needs. Here are the key specs to look out for and how to navigate them.MaterialThe material of welding boots is important because it determines the level of protection and durability. Common materials include leather, rubber, and synthetic blends. Leather is highly durable and offers excellent heat resistance, making it a popular choice. Rubber can provide good protection against electrical hazards and is often used in the soles. Synthetic materials can offer a balance of comfort and protection. Choose a material based on the specific hazards you face and the level of comfort you need.

Heat ResistanceHeat resistance is a critical spec for welding boots as it ensures your feet are protected from high temperatures and sparks. Boots with higher heat resistance can withstand prolonged exposure to heat without degrading. Look for boots that specify their heat resistance rating, often measured in degrees Fahrenheit or Celsius. If you work in environments with extreme heat, opt for boots with higher heat resistance.

Toe ProtectionToe protection is essential to safeguard your feet from falling objects and heavy equipment. Welding boots typically come with steel, composite, or aluminum toe caps. Steel toes offer the highest level of protection but can be heavier. Composite toes are lighter and do not conduct electricity, making them suitable for electrical work. Aluminum toes are also lightweight but provide less protection than steel. Choose the type of toe protection based on the level of impact risk in your work environment.

Sole ConstructionThe construction of the sole affects the boot's grip, stability, and resistance to punctures and slips. Look for soles made from durable materials like rubber or polyurethane, which offer good traction and are resistant to oils and chemicals. Some soles are designed with specific tread patterns to enhance grip on different surfaces. If you work in slippery or uneven environments, prioritize boots with high-quality, slip-resistant soles.

Comfort and FitComfort and fit are crucial for long hours of wear. Welding boots should provide adequate cushioning, arch support, and a snug fit without being too tight. Consider features like padded collars, insoles, and breathable linings that enhance comfort. It's important to try on boots with the socks you plan to wear during work to ensure a proper fit. If you have specific foot issues, look for boots that offer additional support or customization options.

Electrical Hazard ProtectionElectrical hazard protection is important if you work in environments where you may be exposed to live electrical circuits. Boots with this feature are designed to reduce the risk of electric shock by providing insulation. Look for boots that are labeled as EH-rated, which means they meet specific safety standards for electrical hazard protection. If your work involves electrical components, prioritize boots with this rating.

DurabilityDurability ensures that your welding boots will last through tough conditions and frequent use. High-quality materials, reinforced stitching, and robust construction contribute to the overall durability of the boots. Check for features like double or triple stitching, reinforced toe and heel areas, and high-quality zippers or laces. If you work in demanding environments, invest in boots known for their long-lasting performance.

Most Popular Categories Right Now