10 Best Wire Cutter For Jewelry Making 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

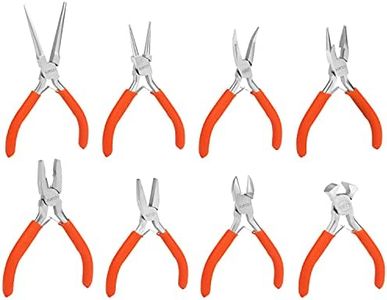

Shynek Jewelry Pliers, 3pcs, Tools with Needle/Chain Nose Pliers, Round Nose Pliers and Wire Cutter for Jewelry Repair, Wire Wrapping, Crafts, Jewelry Making Supplies

Most important from

11478 reviews

The Shynek Jewelry Pliers set includes three essential tools: needle nose pliers, round nose pliers, and a wire cutter, making it a versatile choice for jewelry making, repair, and other DIY crafts. The pliers are made from alloy steel, ensuring durability and long-lasting use. The wire cutter in this set can handle cutting thin metal wire up to 1mm, suitable for most jewelry projects. The flat blades on the cutter allow for precise cuts close to the edge of your work, minimizing the need for further filing or finishing.

One of the standout features is the ergonomic rubber handles, providing comfort during use and reducing hand fatigue, which is crucial for intricate jewelry work. Additionally, the pliers are coated with oil to prevent rust, though users should be aware that this may need to be wiped off before use. The set does not explicitly mention a spring mechanism, which could affect the ease of repeated use, as a spring mechanism typically helps in reducing hand strain by automatically reopening the pliers.

The pliers’ multi-colored design makes it easy to differentiate between tools during a project. This set is particularly beneficial for beginners and hobbyists in jewelry making due to its comprehensive range of tools and user-friendly design.

Most important from

11478 reviews

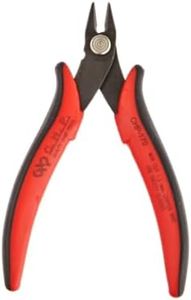

Hakko-CHP-170 Micro Cutter - Red

Most important from

21674 reviews

The Hakko-CHP-170 Micro Cutter is a solid choice for jewelry makers looking for a tool that can handle precise cuts on soft wires up to 16 gauge. Its 8mm long jaw and angled head make flush-cutting a breeze, which is essential for creating clean finishes on your pieces. Made from heat-treated carbon steel, the cutter promises durability and longevity, key traits for any tool in a busy workshop.

One of the standout features is its ergonomic design. The dolphin-style nonslip grips ensure comfort and control during use, which is especially important during long crafting sessions to reduce hand strain. Additionally, the spring mechanism allows the cutter to return to an open position automatically, minimizing operator fatigue—a thoughtful touch for anyone who spends considerable time cutting wire.

The Hakko-CHP-170 Micro Cutter is a great fit for hobbyists and professionals engaged in jewelry-making who require precision and comfort in their tools. Just keep in mind its best applications for softer wires to make the most of its capabilities.

Most important from

21674 reviews

Mr. Pen- Jewelry Pliers, 3 Pack, Jewelry Making kit, Pliers for Jewelry Making, Mini Pliers, Wire Cutters for Jewelry Making, Chain Nose Pliers, Craft Pliers, Earring Pliers

Most important from

4762 reviews

The Mr. Pen Jewelry Pliers Kit is a versatile toolset ideal for both professional and DIY jewelry makers. It includes needle-nosed pliers, round-nosed pliers, and side cutters, each with ergonomic handles in shades of blue, green, and red for comfort during extended use. The alloy steel construction ensures durability, while the ergonomic grip enhances control and comfort during delicate operations.

The round-nosed pliers are particularly helpful for forming loops and curves, making intricate designs easier. The needle-nosed pliers are versatile for picking, placing, shaping, and holding small objects, which is crucial for detailed jewelry work. The side cutters effectively snip wires, making them a key tool in the kit. However, users should note that the pliers come coated with oil to prevent rust, which requires wiping before use and reapplication before storage to maintain their condition.

The kit's compact size makes it portable and convenient to store. This kit is a reliable choice for anyone from hobbyists to professionals looking for a comprehensive pliers set for jewelry making.

Most important from

4762 reviews

Buying Guide for the Best Wire Cutter For Jewelry Making

Choosing the right wire cutter for jewelry making is essential for achieving clean cuts and ensuring the longevity of your tools. The right wire cutter can make your jewelry-making process smoother and more enjoyable. When selecting a wire cutter, consider the type of wire you will be working with, the precision you need, and the comfort of the tool. Here are some key specifications to help you make an informed decision.FAQ

Most Popular Categories Right Now