We Use CookiesWe use cookies to enhance the security, performance,

functionality and for analytical and promotional activities. By continuing to browse this site you

are agreeing to our privacy policy

10 Best Wire Splice Connectors 2025 in the United States

How do we rank products for you?

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Buying Guide for the Best Wire Splice Connectors

When it comes to choosing wire-splice connectors, it's important to understand that these small components play a crucial role in ensuring a secure and reliable electrical connection. The right wire-splice connector can make a significant difference in the performance and safety of your electrical system. To make an informed decision, you need to consider several key specifications that will help you select the best fit for your needs.Wire Gauge CompatibilityWire gauge compatibility refers to the range of wire sizes that a connector can accommodate. This is important because using a connector that is not compatible with your wire gauge can result in poor connections or even damage to the wires. Wire gauges are typically measured in American Wire Gauge (AWG) units. Connectors are often rated for a specific range of wire gauges, such as 22-18 AWG or 12-10 AWG. To pick the right one, you need to know the gauge of the wires you are working with and ensure the connector you choose can handle that size.

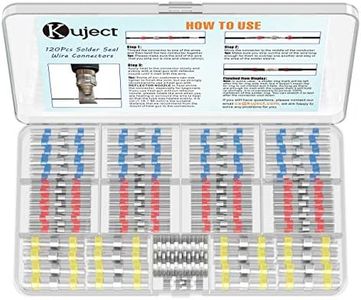

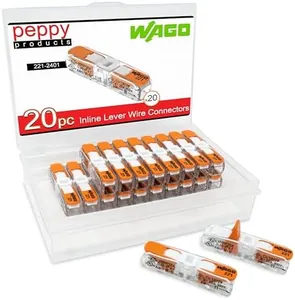

Connector TypeThere are various types of wire-splice connectors, including butt connectors, twist-on wire connectors, and push-in wire connectors. Each type has its own advantages and is suited for different applications. Butt connectors are commonly used for inline splicing, twist-on connectors are great for quick and easy connections, and push-in connectors offer a tool-free installation. Consider the nature of your project and the ease of installation when choosing the connector type that best fits your needs.

Insulation MaterialThe insulation material of a wire-splice connector provides protection against electrical shock and environmental factors. Common insulation materials include vinyl, nylon, and heat shrink. Vinyl is cost-effective and suitable for general use, nylon offers better durability and resistance to chemicals, and heat shrink provides a watertight seal and is ideal for outdoor or harsh environments. Choose the insulation material based on the conditions in which the connectors will be used and the level of protection required.

Current RatingThe current rating of a wire-splice connector indicates the maximum amount of electrical current it can safely carry. This is crucial for ensuring that the connector can handle the electrical load without overheating or failing. Current ratings are usually measured in amperes (A). To select the right connector, you need to know the current requirements of your electrical system and choose a connector with a rating that meets or exceeds that requirement.

Temperature RatingThe temperature rating of a wire-splice connector specifies the maximum temperature it can withstand without degrading. This is important for applications where the connectors will be exposed to high temperatures. Temperature ratings are typically given in degrees Celsius (°C). If your project involves high-temperature environments, such as automotive or industrial applications, make sure to choose connectors with a suitable temperature rating to ensure long-term reliability.

Environmental ResistanceEnvironmental resistance refers to the connector's ability to withstand exposure to moisture, dust, chemicals, and other environmental factors. This is particularly important for outdoor or industrial applications where connectors may be exposed to harsh conditions. Look for connectors that are rated for environmental resistance, such as those with IP (Ingress Protection) ratings, to ensure they can handle the specific conditions of your project.

Most Popular Categories Right Now