10 Best Wire Stripping Machines 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

CREWORKS Electric Wire Stripper Machine, 0.06"-1" Automatic Wire Stripping Machine, Wire Stripping Tool for 1.5-25 mm Scrap Wire, 5 Channel Copper Wire Stripper Power Tool for Leftover Cable Recycling

Most important from

2510 reviews

The CREWORKS Electric Wire Stripper Machine is a versatile and efficient tool designed for stripping insulation from a variety of wire sizes. It can handle wires ranging from 0.06 to 1 inch in diameter, making it suitable for most common jobs. The machine operates at a fast stripping speed of up to 98 feet per minute, driven by a robust 180W motor. This speed and power make it effective for high-volume wire stripping tasks. The five separate feed holes cater to different wire sizes, which adds to its versatility and ease of use.

Additionally, the machine features an adjustment knob to set the blade height precisely, ensuring clean cuts and safe operation. An emergency stop button enhances safety, providing a quick way to halt the machine if necessary. The blade, made of alloy steel, is durable and maintains its sharpness, while the aluminum frame assures long-lasting use. At 28.2 pounds, it may not be the lightest option for those needing frequent portability, though it is designed to be easy to carry around.

The machine is powered by an AC source and does not require batteries, which could be seen as an advantage or a limitation depending on the user's needs. Users have generally rated it highly, with a 4.5 out of 5 stars from over 2,400 reviews, indicating general satisfaction with its performance and reliability. The CREWORKS Wire Stripper is best suited for those needing a reliable and efficient tool for recycling scrap wire, whether in a workshop, shed, or worksite.

Most important from

2510 reviews

CREWORKS Manual Wire Stripper Machine, 0.06"-1" Wire Stripping Machine, Wire Stripping Tool for 1.5-25mm Scrap Wire, Drill Powered Cable Stripper for DIY Cable, Copper Wire Stripper for Leftover Cable

Most important from

3434 reviews

The CREWORKS Manual Wire Stripper Machine is designed with versatility and ease of use in mind, making it a handy tool for DIY enthusiasts and those working with scrap wire. Its ability to handle a wide range of wire sizes, from 0.06 inches to 1 inch, means it can accommodate most common wires you might encounter.

The inclusion of an adjustment knob allows for precise control over the blade height, ensuring clean cuts every time, which is crucial for maintaining the quality of your stripped wire. The option to connect it to a power drill for automatic cranking adds to its ease of use, reducing manual effort significantly when dealing with larger volumes of wire.

Constructed from durable aluminum alloy steel, it promises longevity and dependable performance. The machine’s portability is another strong point, enabling you to easily transport it from one place to another as needed. Its sturdy build, versatility in wire sizes, and additional automatic cranking option make it a valuable tool for anyone regularly dealing with wire stripping tasks.

Most important from

3434 reviews

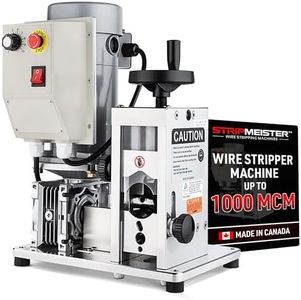

StripMeister Original Drill-Powered Wire Stripper Machine - Manual Wire Stripping Made Easy, Copper, Electric, and Stripping Drill Attachment Tool

Most important from

4236 reviews

The StripMeister Original Drill-Powered Wire Stripper Machine is an efficient and portable tool designed for stripping various types of wires, including copper and braided wires. It supports a wide range of wire sizes, from 18 gauge to 250 MCM, making it versatile for different wire stripping needs. The integration with a drill enhances its stripping speed, reducing manual effort and increasing productivity. The ultra-grip wire feeder technology ensures that wires are fed through smoothly, minimizing slippage and jams, which can be a significant time-saver especially when dealing with kinked or twisted cables.

The machine is lightweight and compact, making it easy to transport and store, ideal for those who need to move their tools frequently or have limited workspace. Constructed with durable materials like aluminum and alloy steel, it promises longevity and reliability. However, the need for a separate drill to power the machine could be a drawback for some users who do not already own one. Additionally, while the machine is effective for a wide range of wire sizes, users with very specific or smaller wire stripping needs might find the range excessive.

Most important from

4236 reviews

Buying Guide for the Best Wire Stripping Machines

When choosing a wire-stripping machine, it's important to consider several key specifications to ensure you select the best fit for your needs. Wire-stripping machines are used to remove the insulation from electrical wires, making them essential for various electrical and manufacturing tasks. Understanding the different features and how they align with your requirements will help you make an informed decision.FAQ

Most Popular Categories Right Now

![RIEDHOFF Automatic Wire Stripping Machine for 0.06" -0.98",[High Precision] Wire Stripper Tool for 7/0-15 AWG, Electric Wire Stripper for Scrap Cable Copper Recycling](https://images-proxy.bestreviews.guide/8zbUfGJZ9sOFa0VrqEO6M_gGybI=/0x300/https://m.media-amazon.com/images/I/51UwvwZXKpL._AC_CX679_.jpg)