10 Best Bench Vises 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

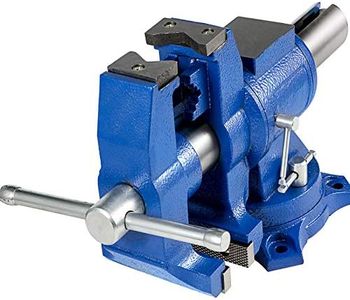

VEVOR Bench Vise, 6-inch Jaw Width 5.9-inch Jaw Opening, 360-Degree Swivel Locking Base Multipurpose Vise w/Anvil, Heavy Duty Ductile Iron Workbench Vise w/Bolts & Nuts, for Drilling, Pipe Cutting

The VEVOR Bench Vise is a solid choice for anyone looking for a sturdy and versatile tool. With a jaw width of 6 inches and a jaw opening of 5.9 inches, it offers ample space for a variety of tasks. The throat depth of 3.5 inches is sufficient for most everyday uses. One of its standout features is the 360-degree swivel base, which allows you to position your workpiece at any angle, providing great flexibility and accuracy without the need to constantly reposition the item you are working on.

The vise is crafted from 60,000 PSI ductile iron, which ensures durability and strength, while the powder coating helps prevent rust. The carbon steel jaw plates are replaceable, offering a strong grip on materials. The anvil area is also quite generous, adding to its functionality for hammering and shaping tasks. Users will appreciate the included accessories like nuts, screws, and magnetic jaw pads, which make installation straightforward and negate the need for additional purchases.

The vise is versatile enough to handle flat materials and pipes with equal ease, making it suitable for a range of projects from drilling to grinding. At 25 pounds, it is on the heavier side, which might be a consideration for those who need to move it frequently. The VEVOR Bench Vise provides robust performance and flexibility for medium to heavy-duty tasks, making it a great fit for professionals and serious DIY enthusiasts.

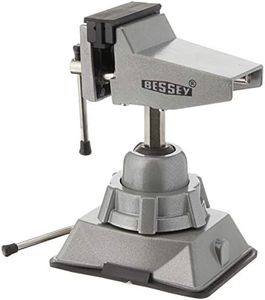

Wilton Multi-Purpose Bench Vise, 5-1/2" Jaw Width, 5" Max Jaw Opening, 2-3/4" Throat (Model 550P)

The Wilton Multi-Purpose Bench Vise (Model 550P) offers a reliable and versatile option for both amateur and professional use. It features a 5-1/2 inch jaw width and a maximum jaw opening of 5 inches, providing ample space for a wide range of clamping tasks. The 2-3/4 inch throat depth allows for deeper materials to be securely clamped. Made from durable ductile iron and cast iron, this vise is built to last and withstand heavy usage.

The 360-degree rotating head allows for clamping at any angle, with indexing at 30-degree increments for quicker, more convenient setups. Additionally, the vise includes replaceable hardened steel jaws with a serrated pattern for better grip and longevity, as well as V-jaws to easily hold round stock vertically. The large built-in anvil is a handy feature for forming and shaping materials.

One notable advantage is Wilton's lifetime warranty against manufacturing defects, offering peace of mind for long-term use. However, at 40 pounds, it is quite heavy, which may be cumbersome for some users to move around. The Wilton 550P is a robust and flexible bench vise, well-suited for anyone in need of a dependable tool for various clamping and forming tasks.

Forward HY-DT150B-6IN Heavy Duty Bench Vise 360-Degree Swivel Base and Head with Anvil (6")

Most important from

2198 reviews

The Forward HY-DT150B-6IN Heavy Duty Bench Vise is a solid choice for both industrial and DIY home use. Key features include a 6-inch jaw width, a 5-inch jaw opening, and a throat depth of 2 5/8 inches, ensuring it can handle a variety of tasks. The vise is constructed from high-strength cast iron and ductile iron, making it durable and capable of withstanding a clamp force of at least 6500 lbs. This makes it suitable for heavy-duty applications.

It offers versatility with its 360-degree swivel base and rotating front head, allowing you to clamp objects at any angle easily. Additionally, it comes with three sets of well-machined jaws: replaceable top jaws with microgroove teeth, built-in pipe jaws, and V-jaws, providing a secure grip for different types of workpieces. The large reinforced anvil is perfect for tasks such as grinding, cutting, and tapping.

At 44.5 pounds, it is quite heavy, which may be a consideration for portability. The vise’s material and construction ensure long-term durability, but its weight might be a con for those needing a more portable option. Its multifunctional design and robust build make it a great addition to any workshop needing a reliable bench vise.

Most important from

2198 reviews

Buying Guide for the Best Bench Vises

When choosing a bench vise, it's important to consider the specific tasks you'll be using it for. A bench vise is a versatile tool that can hold materials in place while you work on them, making it essential for woodworking, metalworking, and other DIY projects. To find the best fit for your needs, you'll need to understand the key specifications and how they impact the vise's performance and suitability for your tasks.FAQ

Most Popular Categories Right Now