10 Best Wilton Bench Vises 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Wilton 8" Mechanics Pro & 6-1/2" Multi-Purpose Bench Vises Bundle (Models 880M & 650P)

Most important from

105 reviews

The Wilton 8" Mechanics Pro & 6-1/2" Multi-Purpose Bench Vises Bundle offers a solid choice for those needing reliable and versatile bench vises. Both vises are made from durable ductile iron, ensuring longevity and robust performance.

The 8" mechanics pro vise stands out with its precision-machined slide bar, which eliminates movement in the front jaw, providing a stable grip regardless of how wide it is opened. Additionally, the enclosed spindle helps maintain smooth operation by keeping lubricants in and contaminants out, making it highly suitable for consistent, heavy-duty usage in industrial settings.

The 6-1/2" multi-purpose vise features a 360-degree rotating head, allowing you to clamp materials at any angle, making it highly versatile for various tasks. It also includes replaceable steel pipe jaws and a large built-in anvil for shaping and forming materials, adding to its functionality. Both vises benefit from Wilton's industry-leading lifetime warranty, providing peace of mind regarding their durability. This bundle is ideal for professionals or serious DIY enthusiasts who need reliable, versatile, and durable bench vises for various applications.

Most important from

105 reviews

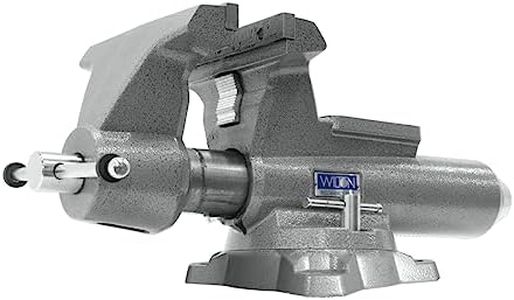

Wilton Mechanics Pro Bench Vise, 8" Jaw Width, 8-1/2" Jaw Opening, 4-1/2" Throat (Model 880M)

Most important from

105 reviews

The Wilton Mechanics Pro Bench Vise is an excellent choice for those in need of a sturdy and reliable tool for various clamping and work tasks. With an 8-inch jaw width and a jaw opening of 8-1/2 inches, it accommodates a wide range of materials, making it suitable for both home workshops and more industrial settings. The 4-1/2 inch throat depth allows for deeper clamping, which is beneficial for thicker workpieces.

One of the standout features of this vise is its construction from 60,000 psi ductile iron, which strikes a balance between durability and weight. This makes it easier to handle without sacrificing strength. The precision-machined slide bar is designed to minimize movement, ensuring that workpieces remain stable even when the jaws are opened significantly. The enclosed spindle design is a thoughtful touch, keeping lubricants contained and preventing dirt from interfering with operation.

The vise also includes a swivel base that rotates a full 360 degrees, providing flexibility in positioning your workpiece. The double lockdowns enhance stability, which is particularly useful when applying significant pressure. Users will appreciate the large anvil work surface, ideal for striking tools. Weighing in at 83.1 pounds, it may be cumbersome for some users, particularly if portability is a concern. Additionally, the clamping force is impressive thanks to the needle roller thrust bearing, though it may require more effort compared to lighter vises, especially for prolonged use.

Most important from

105 reviews

Buying Guide for the Best Wilton Bench Vises

When choosing a Wilton bench vise, it's important to consider the specific tasks you'll be using it for. Bench vises are essential tools for holding workpieces securely in place while you perform various operations such as sawing, drilling, or filing. The right bench vise can make your work easier, safer, and more precise. Here are some key specifications to consider when selecting a Wilton bench vise.FAQ

Most Popular Categories Right Now