10 Best Laser Cutter 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

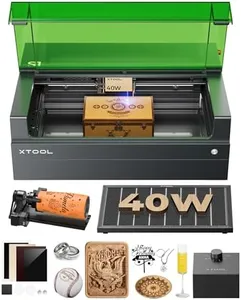

xTool S1 40W Laser Cutter and Laser Engraver for Tumblers, 23.93" x 15.16" Bed Size, 600mm/s Speed, Laser Engraving Machine, Laser Engraver for Wood and Metal, Acrylic, Big Project - Rotary Bundle

Most important from

136 reviews

The xTool S1 40W Laser Cutter and Engraver is a robust machine designed for both beginners and experienced users looking to handle a variety of materials. With its powerful 40W laser, it can easily cut through thick materials like 18mm cherry wood, which is impressive for larger projects, making it ideal for crafting door signs, dog tags, and more. The spacious bed size of 23.93" x 15.16" allows users to work on bigger items without needing to break them down into smaller parts.

One of its standout features is the integration of patented technologies, such as Pin-point Positioning and AutoPassthrough, which enhance precision and facilitate engraving on curved surfaces. Additionally, the user-friendly xTool Creative Space software, equipped with AI capabilities, makes it accessible for those without design skills, offering easy project setup with pre-tested material settings.

Safety is another highlight, as the design includes protective features that filter 99% of laser light, making it safe to use around children and pets. With built-in flame sensors and an emergency stop button, it prioritizes user safety, which is reassuring. There are some points to consider before purchasing. The xTool S1 weighs 79.2 pounds, which may make it cumbersome to relocate. Some users may also find the learning curve with the software a bit steep initially, especially if they are new to laser engraving. Although the machine comes pre-tested for various materials, ensuring compatibility with specific materials outside of what's listed may require additional research. The xTool S1 is a powerful and versatile choice for anyone interested in laser cutting and engraving, particularly those focused on crafting. Its features cater well to different skill levels, though consideration should be given to its weight and potential learning curve.

Most important from

136 reviews

LONGER RAY5 Laser Engraver 20000mW Laser Cutter 130W CNC Laser Cutter with 3.5"Touch Screen Laser Engraving Machine DIY Engraver Tool for Metal Glass Wood Leather Laser Class ii

Most important from

265 reviews

The LONGER RAY5 Laser Engraver is a powerful tool with a 20000mW laser, making it capable of cutting through various materials including pine wood, stainless steel, and acrylic. Its high precision laser technology offers impressive engraving with a 0.01mm accuracy and supports color engraving, offering great creative flexibility. The engraver features a sizable 400*400mm working area and an advanced chipset for efficient multi-machine operations and continuous use, which is a significant plus for productivity.

The 3.5-inch touchscreen and multiple connectivity options (USB, TF card, WiFi, and APP) enhance user convenience and flexibility. Compatibility with popular software like LaserGRBL and LightBurn allows users to choose their preferred software for optimal performance. Safety is prioritized with protective covers, safety glasses, and multiple safety features including emergency shutdown and heat protection. Additionally, the hidden cooling system helps maintain performance and longevity.

The installation is user-friendly with robust customer support, which is a bonus for those new to laser engraving. This laser cutter is ideal for hobbyists, artists, and small businesses looking for a versatile and efficient engraving solution.

Most important from

265 reviews

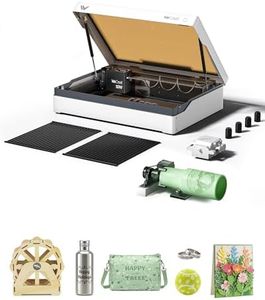

CREALITY FALCON2 22W Laser Engraver Machine with Air Assist and Rotary Roller, 220W High Accuracy Laser Engraver and Cutter Machine for Cylindrical Objects, 25000mm/min Faster Engraving

Most important from

80 reviews

The Creality Falcon2 22W Laser Engraver Machine is a robust option for those seeking a high-power laser cutter. With a 22W laser output, it supports efficient and fast engraving at speeds of up to 25,000mm/min, making it ideal for small businesses or side hustles. Its ability to cut thicker materials like 15mm wood or 10mm black acrylic in a single pass is a significant advantage.

The integrated air assist feature ensures clean and precise cuts by reducing material surface temperature and removing smoke and debris effectively, which benefits the quality of the finished product. Additionally, the 4-in-1 rotary roller is versatile, accommodating various shapes and sizes, which expands its usability for different projects, including cylindrical objects, spheres, and rings. The machine is compatible with popular software like LaserGRBL and LightBurn, supporting both Windows and macOS, making it accessible for most users.

The added safety features, such as the anti-UV filter acrylic cover, emergency stop button, and safety lock, enhance user safety. However, it has a relatively hefty weight of 27.9 pounds and might require a dedicated space for operation due to its dimensions (24.97 x 5 x 28 inches). The assembly process is straightforward, taking about 10-20 minutes, which is a plus for ease of use. On the downside, the machine could be overkill for hobbyists or those with less demanding engraving needs. Moreover, while it is versatile in terms of material compatibility, it might not be suitable for extremely delicate or ultra-high precision tasks.

Most important from

80 reviews

Buying Guide for the Best Laser Cutter

Choosing the right laser cutter can be a daunting task, but understanding the key specifications can help you make an informed decision. Laser cutters are versatile tools used for cutting, engraving, and marking a variety of materials. The right laser cutter for you will depend on your specific needs, such as the types of materials you plan to work with, the level of precision required, and the size of the projects you intend to undertake. By focusing on the key specifications, you can find a laser cutter that meets your requirements and fits your workflow.FAQ

Most Popular Categories Right Now